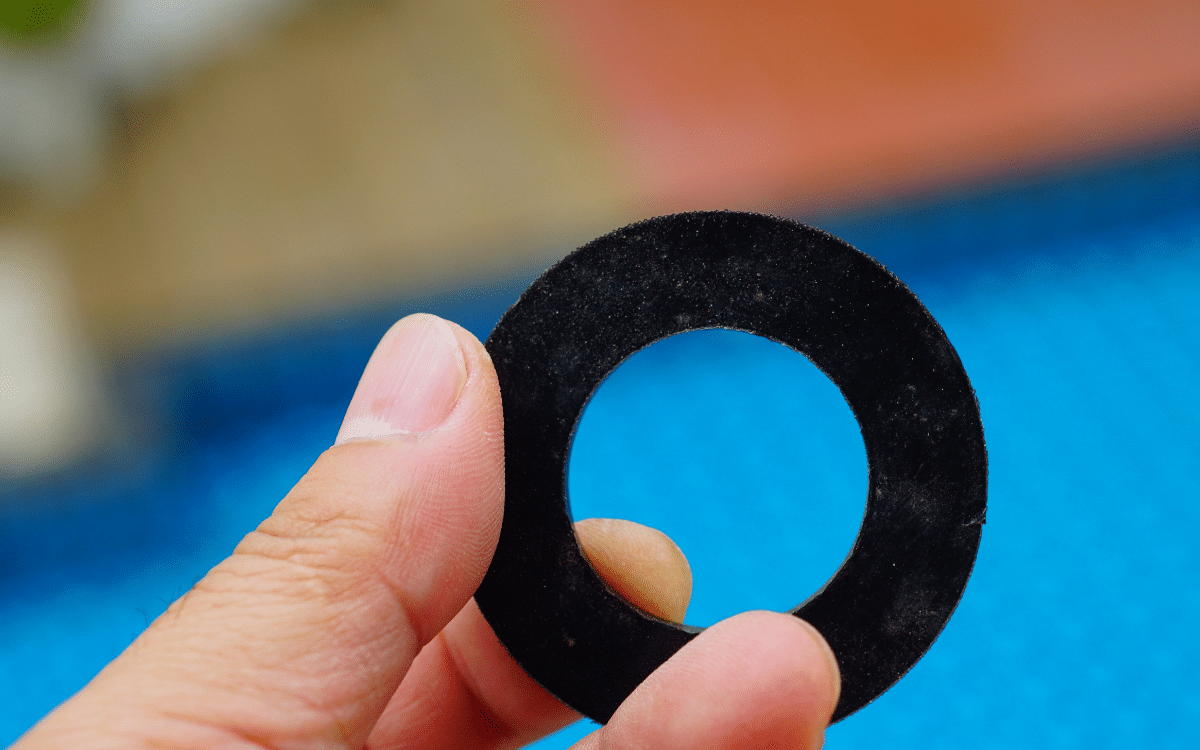

Rubber gaskets are indispensable in industrial manufacturing and offer many benefits. Their applications are broad and critical for maintaining the functionality and efficiency of industrial equipment, from sealing and protecting fluid and gas systems to providing insulation and resisting harsh chemicals.

When choosing a gasket, different materials can support various functions, including industrial gaskets and O-rings for extreme conditions and high-pressure environments.

As industrial technology and processes evolve, so do the materials and designs of rubber gaskets, ensuring they’re at the forefront of industrial innovation. Today, we’ll explore different types of gasket material and their common applications.

5 Rubber Gasket Materials and Applications in Manufacturing

Rubber seals and gaskets are available in various firmness levels and can be custom-cut to meet your specific design requirements. They are made from a variety of materials, including:

Next, we’ll examine the different types of gasket applications to help you determine which material is best for your project.

1. Sealing in Fluid, Air, and Gas Systems

One primary use of rubber gaskets in industrial settings is to create leak-proof seals in fluid and gas systems. Silicone rubber gaskets, such as BISCO® Silicones, help prevent liquid leakage, gases, and vapors under high pressure or extreme conditions, such as high and low temperatures. Industries such as petrochemicals, oil and gas, and water treatment rely on high-pressure gaskets to ensure the integrity of their pipelines, valves, and flanges.

Gaskets are also critical for heating, ventilation, and air conditioning (HVAC) systems. They create airtight seals in ductwork, ensuring efficient temperature control and preventing air leaks. Rubber gaskets help to maintain system efficiency and lower energy costs.

Neoprene gaskets are commonly used in HVAC, automotive, and industrial applications to seal joints, prevent leaks, and prevent exposure to oils, ozone, and harsh conditions. They are also valued for their durability and flexibility, making them suitable for indoor and outdoor use.

2. Vibration Dampening in Machinery

Vibration is a common issue leading to equipment failure and operational efficiencies. In manufacturing environments where heavy machinery is constantly running, rubber gaskets, bumpers, and spacers are often used to absorb vibrations and reduce noise, enhancing machinery performance.

Rubber O-rings and gaskets maintain flexibility and performance even under continuous vibration. They also help reduce operational noise, creating a more comfortable work environment.

3. Electrical Insulation

Silicone or Neoprene rubber gaskets are excellent insulators in electrical enclosures, preventing short circuits, electrical shocks, and electrical failure. In industries that work with sensitive electrical components or high-voltage systems, rubber gaskets provide an additional layer of protection.

Rubber gaskets act as barriers to electricity and safeguard sensitive electrical systems from moisture, dust, and other contaminants that could cause damage.

4. Chemical Resistance in Harsh Environments

Industrial manufacturing often involves using corrosive chemicals in processing plants or pharmaceutical manufacturing. Rubber gaskets made from Viton or EPDM (Ethylene Propylene Diene Monomer) materials are highly resistant to various chemicals. These materials are ideal for use in harsh environments where standard materials degrade quickly as they can withstand exposure to acids, alkalis, and other corrosive substances.

5. Gaskets for EMI/RFI Shielding

Rubber seals and gaskets are used in EMI/RFI aerospace and military applications to seal enclosures and prevent electromagnetic interference (EMI) and radio frequency interference (RFI) from leaking in or out.

EMI/RFI gaskets are commonly used in electronics and communication devices to protect sensitive electrical equipment from interference and catastrophic failure. Often made from conductive elastomers, their airtight seal blocks unwanted signals while maintaining environmental protection, such as moisture or dust resistance.

Choosing the Best Rubber Materials

American Flexible Products can make choosing a customer gasket manufacturer easy. With years of experience, we’re the preferred converter for rubber gaskets and materials used in industrial applications.

We carry a range of solid sheet rubber materials that we customize to your specifications. We can also help you select custom-cut materials based on your application requirements. Contact us today to get started!

[contact-form-7 id=”1783″ title=”Contact AFP”]