Let’s disregard degradation. When you need a gasketing material that degrades at a rate far slower than other flexible materials, neoprene does the job.

Neoprene gaskets have high chemical stability and keep their flexibility even in the most extreme temperatures. This makes them the best option for the worst conditions.

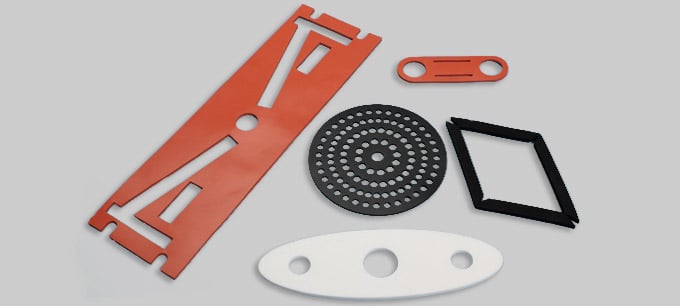

Custom cutting

Gaskets aren’t one-size-fits-all. That’s why we custom cut and shape neoprene into gaskets specific to your design specs. Our materials techs die cut and waterjet cut gaskets in thicknesses ranging from 1.25” down to .031”.

We can also add a layer of pressure-sensitive adhesive backing to your neoprene to make application as easy as fabrication.

Resistance

Neoprene is resistant to alkalis, greases, petroleum-based solvents and various oils.

Temperature Performance

Neoprene performs from -40°F to 230°F and even as high as 250°F on an intermittent basis.

Hardiness

With the ability to twist and flex without damage, neoprene resists degradation better than rubber.

High performance

Neoprene gaskets perform in temperatures as low as -40°F or as high as 230°F. On an intermittent basis, they’ll even keep their stability in temps as high as 250°F.

Neoprene is resistant to alkalis, greases, petroleum-based solvents and various oils, and can twist and flex without damage in many applications. It also holds up to weather elements, ozone and UV radiation.

Uses of Neoprene

Neoprene has uses that go far beyond gasket manufacturing. It’s a common material in noise isolation and padding in athletic gear, wet suits, laptop sleeves and construction joint filler.

Neoprene is also used for fire-resistant weather stripping around doors and windows in commercial and residential buildings.

Ready to get started on your gaskets? Give us a call to send us your design specs or to get questions answered by our engineers.

Every call, question and quote request will be answered by an owner.