Precise, High-Powered Cuts

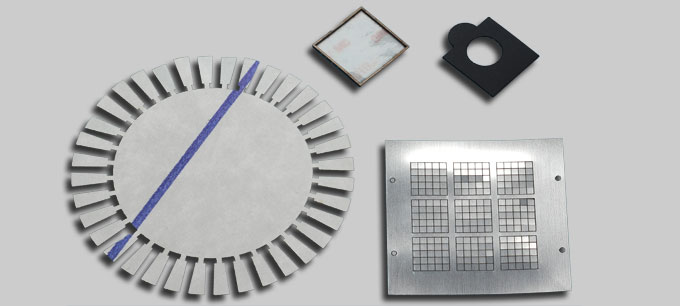

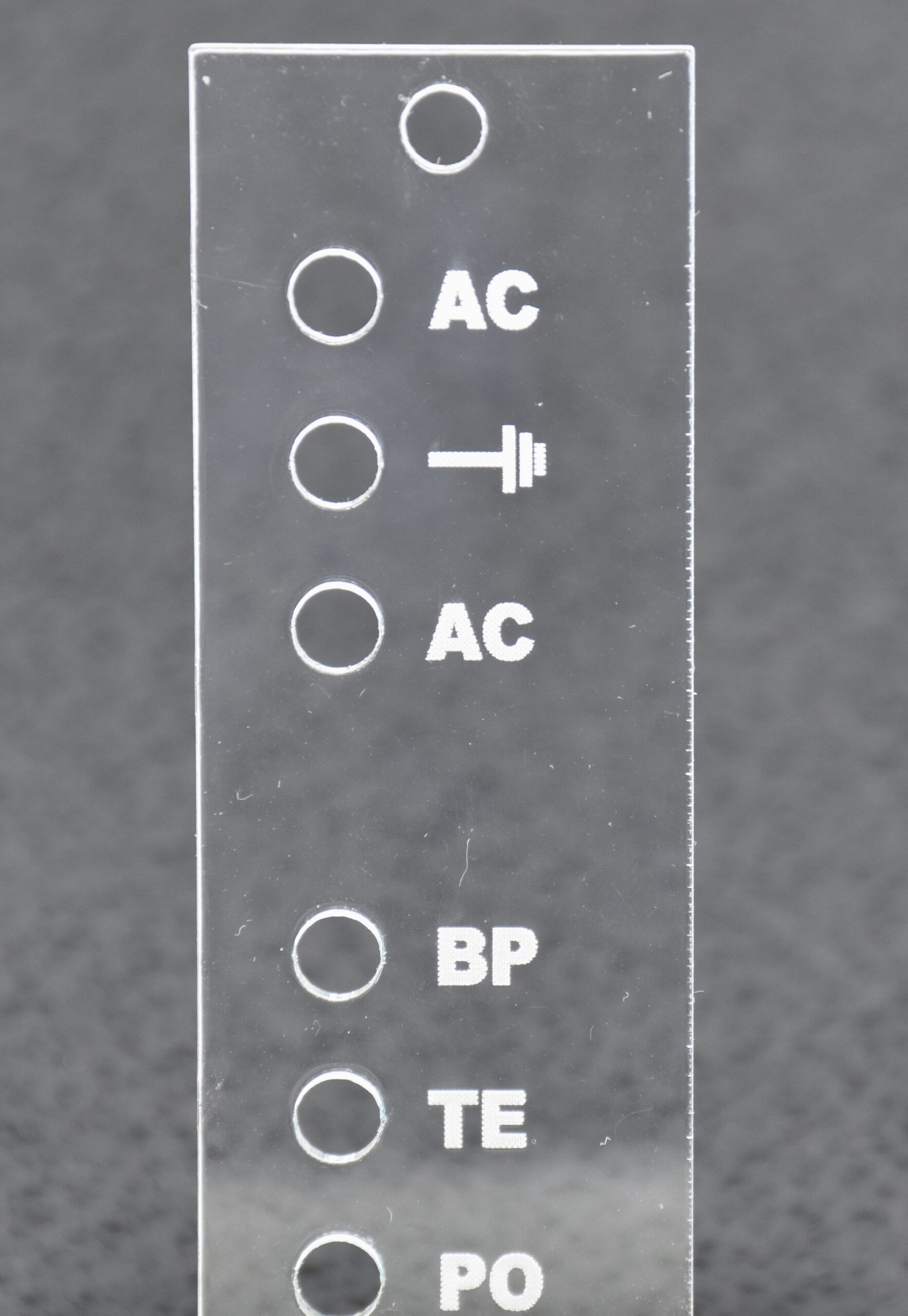

To shape the tightest, most complex design specs, our engineers harness the power of light. Laser cutting uses a powerful, tightly focused laser beam to make accurate cuts and etches into virtually any of our materials.

Using industrial, computer-controlled equipment, laser cutting allows for the speed and precision needed to shape your parts.

When to Use Laser Cutting

Laser cutting and laser etching are used for both miniature and large parts, as well as for prototype and production quantities.

Our materials techs use laser cutting to shape your parts in three ways:

Single-layer cutting slices through the entire material

Multi-layer cutting allows the laser beam to cut through two or more materials

Laser kiss cutting leaves each cut part on an adhesive release layer

Benefits of Laser Cutting

- Tight tolerances

- Intricate shapes and unique designs

- Small feature size

- Quick turnaround

- High speeds

- Versatility

- Cost-effectiveness

Wondering if laser cutting is right for your parts? Give us a call to talk with one of our engineers. We’ll help you decide which type of shaping is best for your project.

Every call, question and quote request will be answered by an owner.