At American Flexible Products, our expert fabricators assist thousands of customers in manufacturing custom parts every year. We do so using a wide range of flexible materials, including:

- Silicones

- Urethanes

- Rubbers

- Foams

- Thin Gauge Plastics

- Adhesives

When it comes to custom fabrication, choosing the right material is an important step in the process and crucial for upholding the function of the equipment in which the part is installed. To save you time and to help you make a more informed purchasing decision, we’re listing some of the most popular flexible materials that our team uses to fabricate items like seals and gaskets, pads, and more.

Rogers PORON Urethane Foams

Rogers PORON foam is a type of microcellular urethane foam that is commonly utilized in the creation of seals, gaskets, battery mounting pads, protective gear, and other products. Its durability, high energy absorption, and compression set resistance are well-known characteristics of this type of PORON foam. Components that are fabricated using Rogers PORON foam are highly coveted due to their consistent compression and continuous performance attributes. Its open-cell design provides greater longevity and resilience, even after multiple impacts, allowing equipment to use PORON foam for years or even decades without losing its shape.

Rogers BISCO® Silicones

Our skilled product converters specialize in utilizing BISCO® silicone, a unique material with the ability to endure a vast range of temperatures, ranging from -55C to 205C. What’s unique about this type of silicone is that it can uphold its physical characteristics for numerous years, making it a dependable option for various applications. Other materials like polyurethanes, EPDMs, and EVAs don’t have the same level of durability as silicone. As a Rogers BISCO® Preferred Converter, American Flexible Products is a reputable provider of silicone gasketing solutions.

Plastics

The usage of plastics has become ubiquitous in our daily lives. Over the past few decades, we have increased our plastic consumption in a big way, producing more malleable, adaptable, and multifunctional products that were previously made with metals. Plastics are utilized in the production of various items, such as signs, enclosures, and insulators.

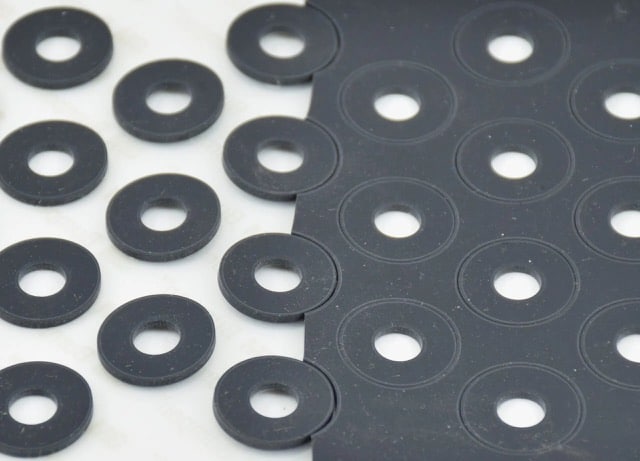

Rubbers

Our team of materials engineers specializes in creating rubber gaskets, spacers, bumpers, and other products using elastomeric materials like rubber. We take your prototyping or final design specifications and produce a product that matches your exact dimensions and desired qualities. We use rubber to produce many products, including:

- Silicone

- Vinyl

- EPDM

- Nitrile

- More

Closed Cell Sponges

Closed cell materials have air bubbles enclosed within them during their manufacturing process. These trapped air bubbles enhance the material’s insulating properties, increase its resistance to liquid water, and result in a more robust and denser material. This type of material is especially useful for sealing applications as it reduces the flow of both gas and liquid. Customers needing a physical barrier for items like isolators, mounting pads, or weather stripping often choose closed-cell sponges as their material of choice. Closed-cell sponge material options include:

- Neoprene

- Nitrile

- PVC Foam

- Silicone

- ECH

- More

Insulators

We rely on electricity constantly, using it in almost every space we occupy. Despite its usefulness, exposed electricity can pose a threat to nearby devices, equipment, and even people. That is why all electrical appliances and systems have some form of insulation. Our materials experts utilize both electrical and thermal insulators during the production of parts. Electrical insulators are employed to avoid arcing in equipment that is currently in use, while thermal insulators are utilized to dissipate the heat generated by such equipment.

RFI and EMI Shielding

EMI and RFI gaskets are essential components for electronic devices to function properly. They are even present in the device that you are currently using. The purpose of these gaskets is to shield the electrical components from excessive energy that can lead to malfunction or complete failure. At American Flexible Products, our experts will help you select, fit, and shape the appropriate EMI and RFI gaskets for your equipment. We use several different materials for RFI and EMI purposes, such as:

- Mu-Metal

- Conductive Rubber

- Foil Tapes

- More

3M Pressure Sensitive Adhesive Tapes

At American Flexible Products, we’re proud to be an official 3M™ Preferred Converter of pressure-sensitive adhesive tapes, also called PSA tapes. When applied to a clean, dry surface with light pressure, PSAs have the ability to adhere to various types of substrates in most applications. The unique characteristics of 3M PSA tapes help boost production efficiency while giving designers more freedom when creating a product.

Choose American Flexible Products for Quality Fabrication

American Flexible Products is a nationwide converter of flexible materials—from foam to rubber to silicone and more. Every product is custom-cut and shaped to your design specs by our materials engineers. If you’re ready to get started on something special, we’re here to help.