Cutting is a common manufacturing process used to transform materials into finished products. It enables manufacturers to alter the size and shape of materials to suit production needs. Water jet and laser are two common cutting methods, but which process is best for your flexible material cutting needs? Let’s first take a look at the basics of waterjet cutting and custom laser cutting.

What is Laser Cutting?

The use of a high-powered laser is the defining characteristic of laser cutting, a cutting method that has been utilized for more than 50 years. Initially, laser-cutting machines were employed in the mid-1960s to create holes in diamonds. Since then, they have become a staple in the manufacturing industry.

Custom laser cutting utilizes light, precision, and high-powered cuts to shape the tightest, most complicated design specs for our clients. It works by using a highly powerful, focused laser beam to perform accurate etches and cuts into just about any flexible material. Like other types of cutting methods, laser cutting can often be automated using computer-controlled equipment, allowing for enhanced speed and precision across the board.

When Should You Use Laser Cutting for Flexible Materials?

Laser cutting and etching are used for small and large parts in both prototype and production. Our materials technicians utilize three laser-cutting techniques:

- Single-Layer Cutting: This cutting process slices through the entire material that needs to be cut.

- Multi-Layer Cutting: This type of cutting lets the laser beam cut through more than one material.

- Laser Kiss Cutting: If you want to leave each cut part on an adhesive release layer, this is the process to choose.

What is Waterjet Cutting?

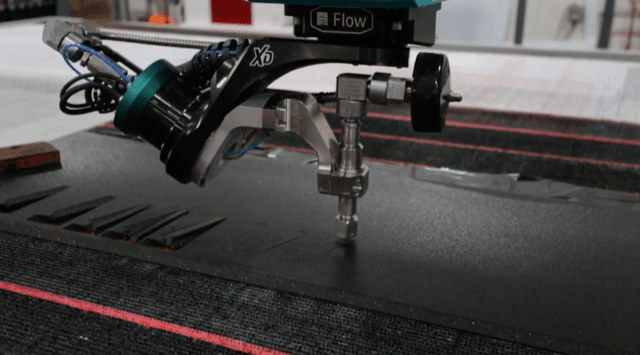

Water jet cutting uses high-pressure water, sometimes with an abrasive, to cut materials. The water runs through a pump and is released through a nozzle in a narrow stream to cut the material. American Flexible Products offers waterjet cutting services that utilize cold water and pressure to shape, shear, and slice parts. The cutting process involves a strong and consistent stream of water that can cut through materials of varying densities. With a maximum pressure of up to 90,000 psi, the resulting output is precise and clean, leaving your product ready for use.

Waterjet Cutting and Laser Cutting for Rapid Prototype Production

When it comes to developing products, rapid prototyping is a fantastic approach due to its precision, cost-effectiveness, and minimal waste production. This method allows for greater flexibility in design options, resulting in speedy development. Both waterjet cutting and laser cutting work well for this type of production.

One of the advantages of using waterjet technology for rapid prototyping is that it doesn’t require any tooling, making the process more efficient. Laser cutting is also a viable option, making it possible for intricate designs and more polished edges without the need for buffing. Laser cutting for rapid prototyping is also popular because there is less maintenance involved – there are no blades that have to be replaced or sharpened.

When Should You Use Waterjet Cutting for Flexible Materials?

When it comes to precise shaping, waterjet cutting is a preferred method as it doesn’t involve heat, which can cause certain materials to warp or burn. Our team of engineers ensures that non-heated water streams and temperature-controlled materials are used to avoid such issues. Waterjet cutting also allows for intricate and complex designs to be cut into your parts. Thanks to our computer-controlled equipment, the accuracy of our waterjets is impressive, with tolerances as low as .025 millimeters, which ensures level and accurate edges, even with thicker material.

When cutting different materials, we often add an abrasive compound to the water stream to create what’s known as “abrasive jet cutting.” This powerful and high-pressure stream of water and abrasive can effectively cut through a wide range of materials, including those with varying densities and multiple layers.

Some of the most common materials that benefit from abrasive jet cutting include the following:

Your Premier Choice for Waterjet and Laser Cutting in Minnesota

American Flexible Products is a nationwide converter of flexible materials—from foam to rubber to silicone and more. Every product is custom-cut and shaped to your design specs by our materials engineers. Curious whether waterjet cutting or laser cutting is best for your parts? Give us a call to talk with one of our engineers. We’ll help you decide which type of shaping is best for your project.