To prolong the lifespan of your electronic devices, it’s crucial to keep them in good working condition. Overheating is a common problem that many devices experience. Thermal pads offer an effective solution to prevent overheating and ensure your devices operate smoothly.

Thermal pads (sometimes referred to as thermal conductivity pads or thermal interface materials) are designed to prevent overheating by conforming into microscopic spaces between the electronic components. Their main purpose is to aid in transferring heat from different components to the heatsink or other cooling device.

Read our detailed guide to learn more about the different types of thermal material and their benefits and uses.

The Benefits of Silicone Thermal Pads

Silicone thermal gap pads have many benefits and advantages, check out these ones.

- Heat Resistance: Silicone pads offer reliable heat resistance, effectively withstanding high temperatures.

- Thermal Conductivity: This type of material has a thermal conductivity of up to 5 W/m-K. Depending on the quality of the silicone, it can be higher.

- Dielectric Strength: Silicone thermal pads possess a dielectric strength of between 10 kV/mm and 20 kV/mm.

- Flame Retardancy: Silicone pads exhibit strong flame retardancy, effectively resisting the spread of flames in case of fire.

- Conformability: Silicone thermal pads have excellent softness and conformability, making them ideal for use in irregular spaces and to fill microscopic gaps.

The Benefits of Acrylic Thermal Pads

For thermal gap pads that are cost-friendly, acrylic is a solid option. Here are the benefits of acyclic thermal pads:

- Heat Resistance: Acrylic pads excel in heat resistance, which is essential for helping devices maintain peak performance and longevity.

- Cost-Effective: This type of material is an excellent money-saving option.

- Thermal Conductivity: The thermal conductivity of acrylic material is up to 4 W/m-K.

- Dielectric Strength: The dielectric strength of acrylic thermal pads is exceptional, with strength values ranging from 5 kV/mm to 10 kV/mm.

- Flame Retardancy: Acrylic pads have good flame retardancy.

- Conformability: Acrylic pads offer flexibility in conformability and softness, making them ideal for application on uneven or irregular surfaces.

Thermal Pad Applications

Both acrylic and silicone materials can be applied to a wide range of electronics, enhancing the performance of devices of various shapes and sizes.

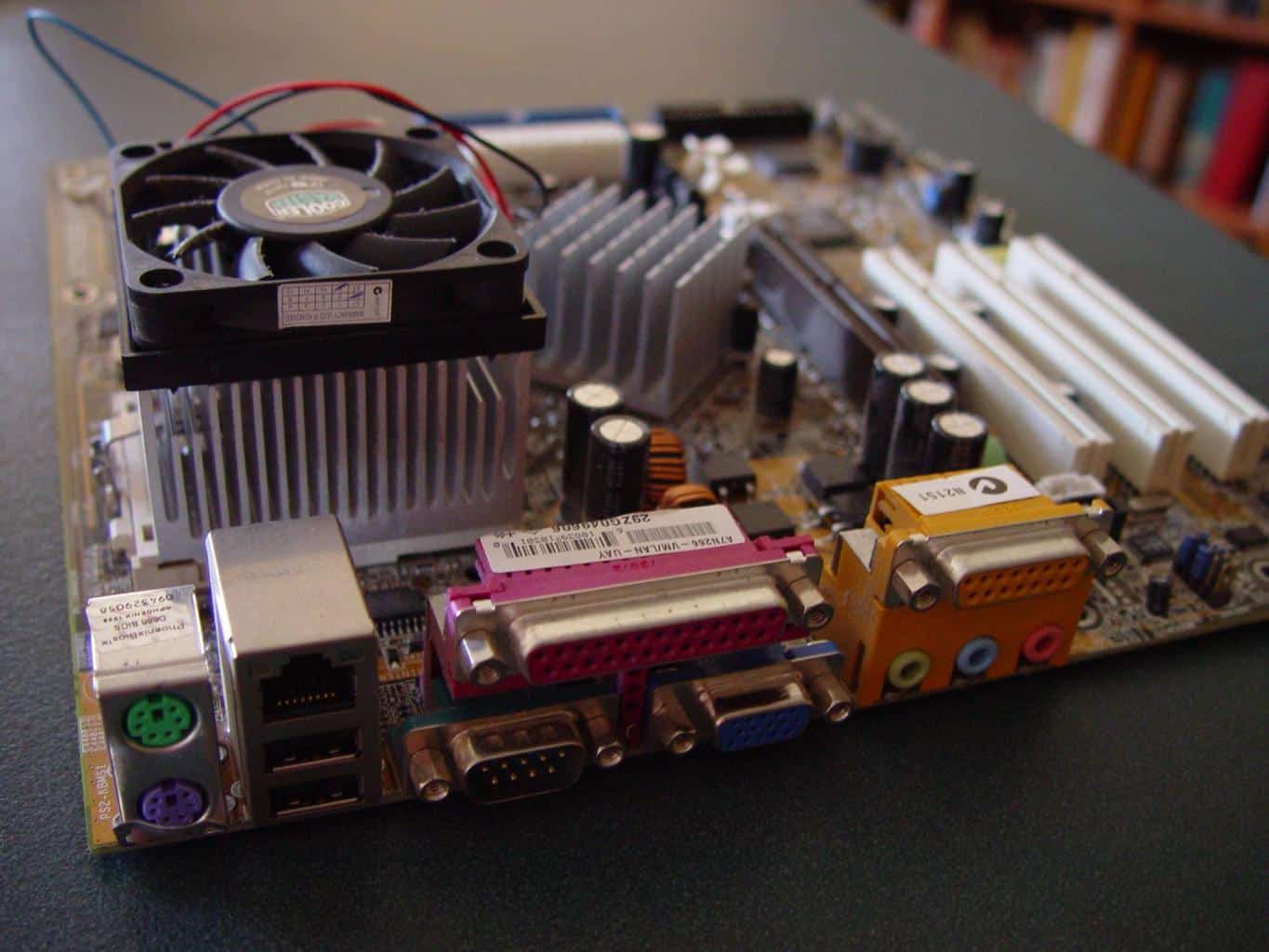

- CPU: Can be used to fill microscopic gaps between the CPU surface and heat sink.

- GPU: Help protect delicate GPU components through their cushioning effect.

- Smartphones and Tablets: Can be used to manage heat between GPUs, heat sinks, and processors to prevent overheating.

- Laptops: Help the device run cooler by dissipating heat from the CPU and GPU to the cooling fans.

- Gaming Consoles: Enhance console performance when applied to processors and graphics cards.

Why Use Thermal Gap Pads?

- Easy to Handle: Are simple to handle due to their solidity, making them easy to apply to different devices.

- Durable Design: Resistant to punctures and tears, offering safe and stress-free applications.

- Conformable and Flexible: Easily conform to uneven surfaces, allowing for better integration.

- Vibration Reducing: Aid in stability and performance by reducing vibrations with their soft design.

How Thermal Pads Enhance Device Performance

Whether you choose to use acrylic or silicone material, you can expect an enhancement in your devices.

- Prevent Overheating: Thermal pads can help prevent overheating by transferring heat away from components such as GPUs and CPUs.

- Enhance Device Performance: By keeping devices cool, they can run at peak performance without degrading.

- Reduces Thermal Stress: By consistently managing heat, thermal gap pads help reduce thermal stress on components. This leads to fewer heat-related failures.

- Supports Battery Life: Thermal pads can help prolong the battery life of portable devices.

Need Custom-Fabricated Thermal Pads?

As a nationwide 3M Preferred Converter of 3M thermal management materials, American Flexible Products can help you find the material you need. We offer custom-cut and shaped products designed to fit your needs. Whether you need rubber or silicone, we’ve got you covered. Contact us, and our material professionals will help you with your next order!