Pressure-sensitive adhesive tape (also called PSA tape) is a large category of adhesive tape, usually constructed of a thin, flexible material that is used to attach to the surfaces of two substrates. In most applications, PSAs will adhere to several types of substrates when it’s applied to a dry, clean surface with light pressure. The Pressure Sensitive Tape Council defines PSA tape by three characteristics:

- No Liquid-to-Solid Phase Change

- Permanent Tack

- Light Pressure Needed for Adhesion

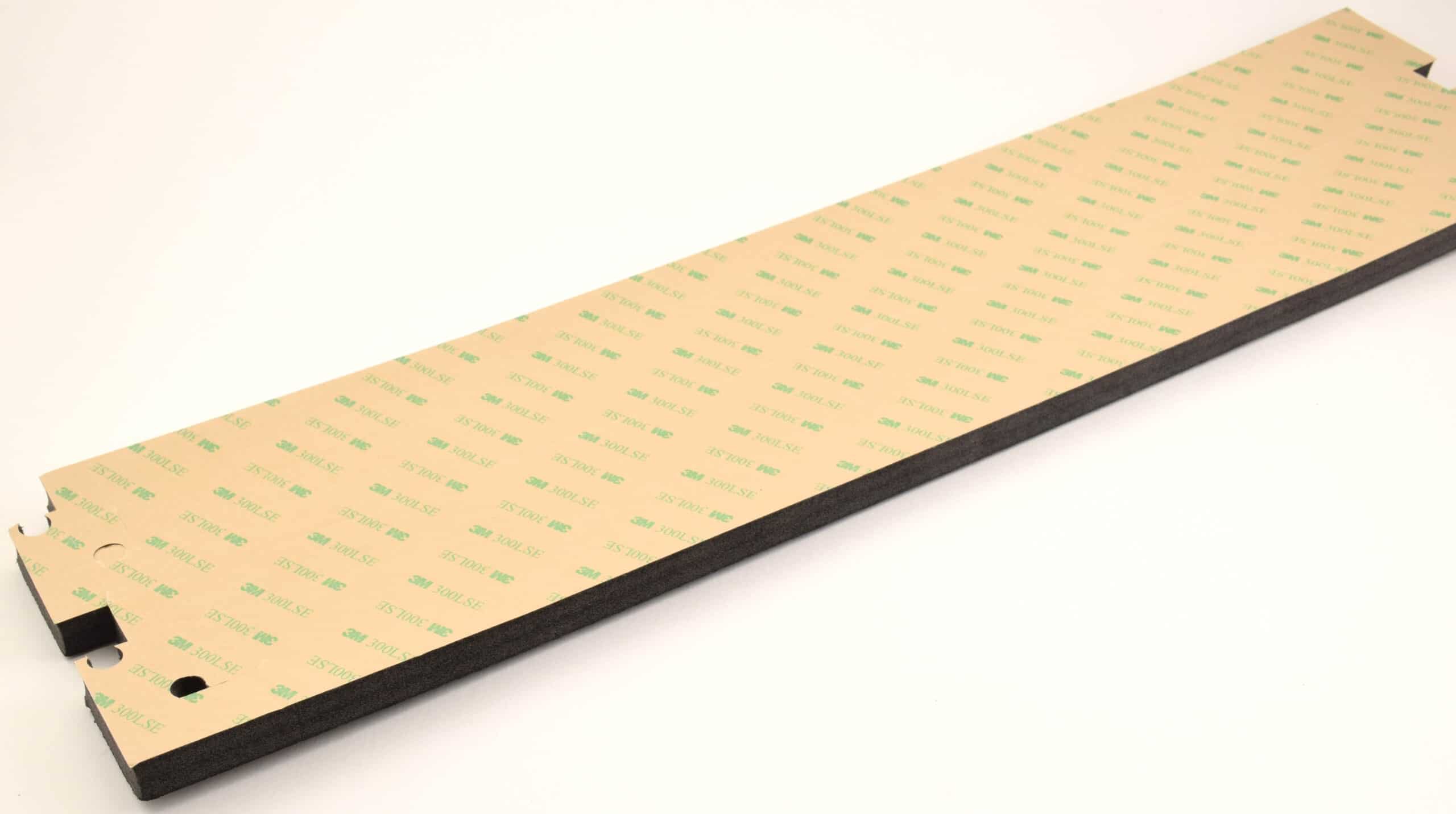

Unlike adhesives that come in liquid form, the chemistry of tape is completely cured right out of the package, meaning there’s no need for additional curing to create a bond. Instead, the bond from 3M pressure-sensitive adhesive tape is formed using electrostatic and mechanical interactions at the interface. The unique characteristics of PSA tape help boost production efficiency while giving designers more freedom when designing a product.

Some of the many benefits of 3M PSA Tape include:

- Bonds Different Materials Together Without Causing Damage to Surfaces

- Easy to Apply

- Application Is Precise with Converted or Preformed Shapes

- Handling Strength Is Instant After Pressure Is Applied

- Bond Thickness Is Consistent

- Several Thickness Options

- Preassembly Is Possible

- Metal-to-Metal Barrier Means Less Galvanic Corrosion

As a general rule, when choosing a tape or pressure-sensitive adhesive, it’s important to account for the surface conditions and environments where the adhesive is being used. Some typical surface condition factors can include cleanliness and flexibility. Typical environments can include temperature range and UV light.

The Most Common Chemistries of PSA Tape

Pressure-sensitive adhesives come in a variety of formats and chemistries for industrial bonding purposes. However, the three most common chemistries include rubber, acrylic, and silicone. Let’s take a look at some advantages of each choice.

Rubber

This type of chemistry is a trailblazer of sorts, as it was the first material used to create pressure-sensitive adhesives. Today, rubber pressure-sensitive adhesives include both synthetic and natural rubber resins.

Many manufacturers use rubber because it has a high tack (or quick initial bond), is a low-cost solution, and can adhere to substrates with low surface energy. Though rubber is versatile by nature, it has a lower final bond strength and lower temperature resistance than acrylic PSAs.

Acrylic

Acrylic first saw use as a pressure-sensitive adhesive when manufacturers saw that natural rubber tended to degrade and become yellow when exposed to UV rays. Today, this type of PSA tape is considered by many as the “workhorse” of industrial bonding, with low and high-temperature performance and the ability to adhere to medium and high surface energy materials.

Acrylic PSA tape from 3M has many advantages, such as its ability to bond with a large variety of materials and its resistance to environmental conditions and aging. Though it takes longer for acrylic to bond, the strength of its final bond is higher than rubber pressure-sensitive adhesives.

Silicone

This type of pressure-sensitive adhesive tape is known for its ability to bond to silicone and withstand a wide range of temperatures. Because silicone is inorganic, it is inherently hypoallergenic and can even resist fungi and molds. Despite its ability to bond with silicone materials, this type of tape can have a lower bonding strength if used with non-silicone options.

American Flexible Products offers a range of products based on the type of adhesive you need:

- Electrically Conductive

- Double Coated (Carrier)

- Low Surface Energy

- High Surface Energy

- Transfer Tape (Free Film)

- VHB (Very High Bonding)

- Optically Clear

- Thermally Conductive

- Repositionable (Low and High Tack)

Get Your Free Quote on 3M™ PSA Tape

At American Flexible Products, we’re proud to be an official 3M™ Preferred Converter. This distinction allows us to custom convert 3M brand products, like pressure-sensitive adhesives, for our customers and their projects. With access to 3M-certified specialists and support, American Flexible Products is a premier choice for all of your bonding and sealing tape needs.

To learn more about 3M pressure-sensitive adhesives and whether our engineers can use durable, long-lasting 3M adhesives and bonding agents in your products, contact us today. We look forward to making something great together!