Kiss cutting is a common technique used in manufacturing to make products like stickers, felt pads and hanging hooks. This process leaves your finished part cut, but on a removable layer of paper or foil. Your finished part stays on this layer until it’s peeled off and used. This makes transportation, organization and application easier for both you and your customers.

When to Use Kiss Cutting

You should use kiss cutting when you want convenience. It’s easier to peel a part off of a large back sheet as opposed to peeling the backing off a part of the same measurements. If you have a large set of parts that need to stay grouped, it’s possible to assemble several finished parts onto one backing layer.

How Kiss Cutting Works

Here are the basic steps of kiss cutting:

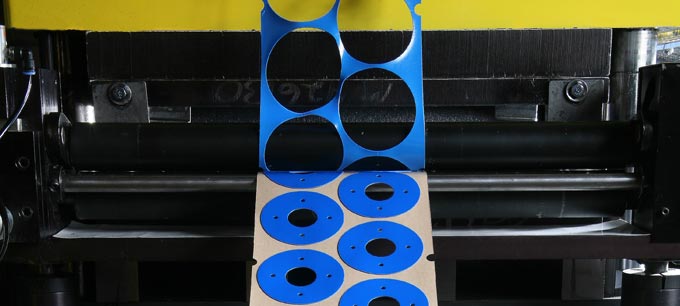

- A layer of raw material (like foam or rubber) is placed on top of a removable paper or foil layer and sent through a kiss-cutting press.

- A sharp steel blade cuts all the way through your part material, but only “kisses” the layer of paper or foil. The result is a cut-shaped product with the backing layer intact.

Need Kiss-Cut Materials For Your Products? Contact Us Today!

Wondering if kiss cutting is right for your products? We’ll help you decide which type of shaping is best for your project.

American Flexible Products is a nation-wide converter of flexible materials—from foam to rubber to silicone and more. Every product is custom-cut and shaped to your design specs by our materials engineers. We are a 3M™ Preferred Converter, which allows us to custom fabricate 3M materials.

Call 952-368-4225 or fill out our form below. Our material experts will help guide you through our process and give you a free quote.