Die cutting, or flatbed die cutting, stamps or blanks out parts of materials like an industrial cookie cutter. Although there are multiple ways to cut flexible materials, including kiss cutting, splitting, slitting, waterjet cutting, or laser cutting, if you’re looking for top precision, die cutting can be a game-changer.

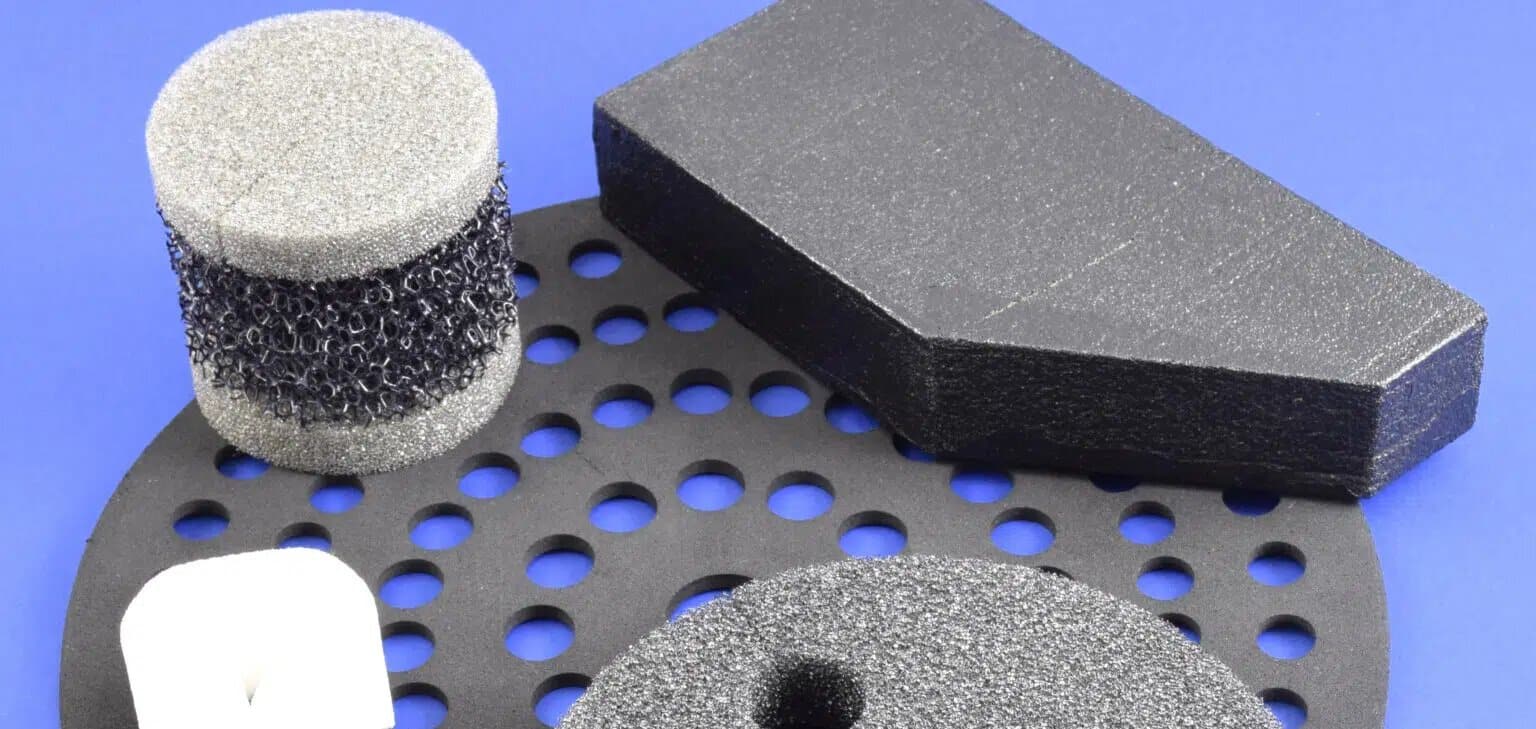

From gaskets to adhesive mounting pads, nearly any flexible material can be die cut. In this article, we’ll discuss how this process works, when to use it for your materials, and the benefits of die cut gaskets.

What Is a Die Cutting Machine?

The press machine works by stamping out each piece using steel rule dies (which are long, sharp metal strips).

How Does It Work?

The hydraulic press falls vertically onto the raw material as it’s fed through the machine. The vertical, perpendicular motion allows thicker and taller material to be used to make your part.

When Should You Use Die Cutting?

Of all the different ways to shape and cut materials, flatbed die cutting is most useful when:

- You want your parts with or without adhesive

- You need a cost-effective manufacturing option

- Your product is thicker

- Your product’s material is only available in sheet form

- Your manufacturing needs to be more cost-effective

Why Is Die Cutting Used for Gaskets?

Gaskets are basically mechanical seals with many important functions—from sealing out dust, water, and debris to stopping EMI/RFI, by sealing two mating surfaces.

While most gaskets are seals by nature, they can be manufactured differently, depending on your needs. For instance, some gaskets are manufactured with water jet cutting, while others are created with die cutting.

Die cutting gaskets is often preferred over water jet cutting for several reasons.

Cost Effectiveness

With die-cutting, you can create parts quickly and effectively. In fact, it’s quicker than other cutting options like waterjet cutting.

Powerful Precision

Die cutting is highly precise due to the use of computer-controlled equipment and sharp cutting tools. As a result, you can trust that your parts are cut exactly to design specifications every single time.

Regulatory and Safety Standards

If your work involves strict adherence to regulatory standards, die-cut gaskets are invaluable. At American Flexible Products, our expert engineers can assist you in selecting designs and materials that meet required standards, ensuring your operations remain compliant and your customers are kept safe.

Pressure and Heat- Resistant

Gasses and fluids that run through machinery can be scorching hot. With heat comes thermal expansion, thus creating pressure. This combination can harm parts, but die-cut gaskets can resist pressure and heat, keeping your parts safe.

How Are Die-Cut Gaskets Created?

To create a die, a sharp cutting tool is bent into a part’s outline and integrated into its base or board for support. When it’s time to create parts, a hydraulic press cuts through the raw material while fed through a die-cutting machine (think of a giant cookie cutter).

The process leaves your product even, clean, and in line with your desired measurements, whether you’re producing simple or complex shapes.

Why Choose AFP for Custom Die-Cut Gaskets?

As a nation-wide converter of flexible materials—from foam to rubber to silicone and more—with more than 30 years of experience, we can ensure that every product is custom-cut and shaped to your design specs.

Even with runs of one hundred, one thousand, ten thousand, or more, we’ve got you covered without ever sacrificing quality or precision. We’re also a 3M™ Preferred Converter, which allows us to custom fabricate 3M materials.

If you’re facing an unusual gasket problem or simply need a part that other shops can’t produce, our team is here to help! Contact us today to speak with one of our engineers.

We’ll help you decide if die cutting or another shaping solution is best for your project.