Water is all around us – we use it for countless purposes, from keeping us hydrated and healthy to putting out fires and saving lives. But when it comes to custom-cut products, water can be incredibly powerful and precise. With waterjet cutting, your parts can be shaped, sheared, and sliced using nothing but cold water and pressure. For that reason alone, waterjet cutting has grown substantially in popularity over the years.

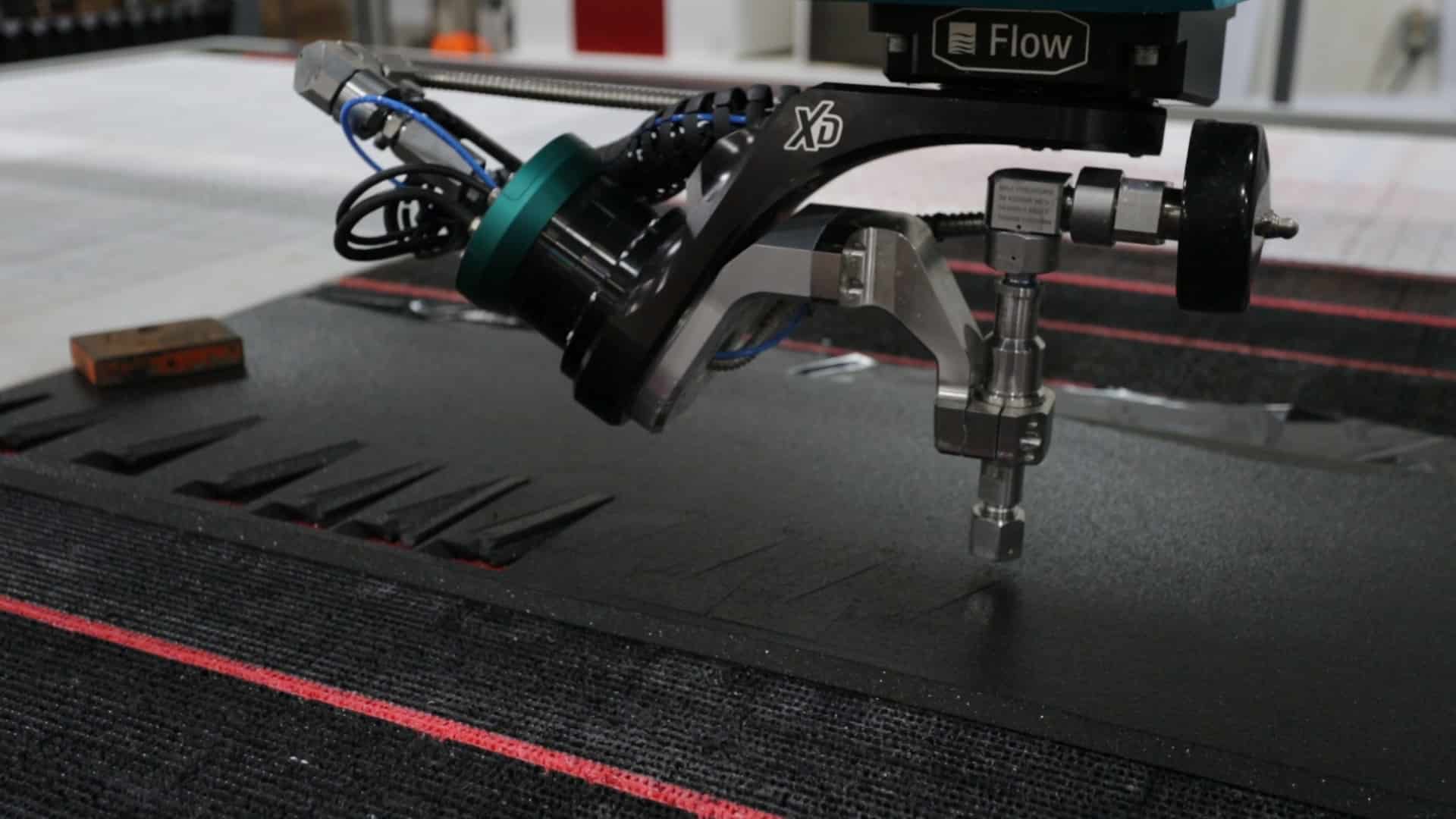

Instead of heat, waterjet cutting involves a high-pressure stream of concentrated water, which slices through a variety of materials like dense rubber, plastic, and silicone with streamlined precision. At American Flexible Products, our waterjet equipment produces a powerful stream of water with a max pressure of 90,000 psi, leaving your end product accurate, clean, and ready to use. And because there’s no heat involved, you won’t have to worry about burned or warped products.

But that’s just the start. Here are some of the other benefits of using waterjet cutting from American Flexible Products.

Precise Cutting

One of the biggest benefits of waterjet cutting is that it is very precise. If your product has intricate designs or requires a very precise type of cut, waterjet cutting is a great option to consider. At American Flexible Products, our computer-controlled waterjet equipment has an accuracy as low as .025 millimeters, creating tight tolerances and level, accurate edges, even when working with thicker materials. And to give our clients more design options, we use a 5-Axis cutting head, allowing us to create 3D designs, beveled edges, and much more. To learn more about waterjet cutting options from American Flexible Products, contact us today to speak with an owner.

Variety of Materials

Waterjet cutting is great for a variety of materials because we can add abrasive compounds to the water stream. This process allows our engineers to cut almost any type of material – even multiple layers of material with different densities. Some of the materials our abrasive jet cutting can handle include:

Material Preservation

Unlike some types of material cutting, waterjet cutting can cut through workpieces without altering its structural integrity. Cutting processes that rely on heat, on the other hand, sometimes alter a material’s physical makeup. That’s because using heat-related cu

tting actually changes the molecular properties of certain materials. This can result in deformed, brittle, or weaker products. Since there’s no heat involved in waterjet cutting, you don’t have to worry about heat-affected zones in any of your products.

No Additional Finishing Needed

Waterjet cutting is often a first choice because it doesn’t leave stains on your material and maintains a high finish. Because of those factors, most materials do not need secondary finishing, which reduces cutting time and boosts efficiency overall.

Eco-Friendly

At American Flexible Products, our waterjet cutting involves a closed-loop process that recycles the water we use for cutting materials. Plus, any cut metal is recycled through the water and used for scrap. In terms of being environmentally friendly, waterjet cutting is near the top of the list.

Get Your Free Waterjet Cutting Quote from American

Flexible Products

American Flexible Products is a nationwide converter of flexible materials—from foam to rubber to silicone and more. Every product is custom-cut and shaped to your design specs by our materials engineers. Wondering if waterjet cutting is right for your parts? Give us a call to talk with one of our engineers. We’ll help you decide which type of shaping is best for your project.

Other forms of product cutting services from American Flexible Products include:

-

- Die Cutting

- Rotary Die Cutting

- Kiss Cutting

- Laser Cutting

- CNC Digital Cutting

- Slitting

- Skiving

- Rapid Prototype Cutting