Durable protection

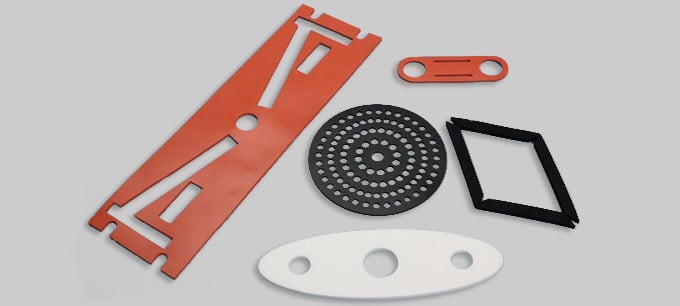

Gaskets and seals are our bread and butter. We take strong, durable material and clean, precise shaping to make your part perfect for your end use.

Have your design specs ready to go? We’ll cut, shape and ship out to get your part done right and on time. Still working on the prototype? Our engineers can help you with everything from material selection to dimensioning to added features like lamination and pressure-sensitive adhesives.

Materials

We craft your part from top-sourced rubbers, foams, silicones and more, all based on your product’s specific uses and environments.

- BISCO silicone

- PORON urethane

- Closed-cell sponge

- Open-cell foam

- Plastics

- Rubbers

- 3M materials

- Neoprene

Cutting and Shaping

We know that your gaskets and seals need to fit unique design specs. That’s why each one of your parts is fabricated directly from our materials and your design—never an off-the-shelf product.

We’ll shape and process your gaskets and seals using:

- Die cutting

- Kiss cutting

- Laser cutting

- Waterjet cutting

- Slitting

- Splitting

- Lamination

- Pressure sensitive adhesives (PSAs)

Electrical enclosure gaskets

Keeping electrical components safe doesn’t stop at surge protectors. Electrical enclosure gaskets and seals are designed to keep water, air, oil, dust and debris from affecting your electrical parts. We can also choose materials based on appearance and aesthetics to create an all-around appealing design.

Our engineers work in compliance with NEMA and UL certification requirements, EMI and RFI considerations, and environmental safety regulations.

Ready to get started on your gaskets or seals? Give us a call to send us your design specs or to get questions answered by our engineers.

Every call, question and quote request will be answered by an owner.