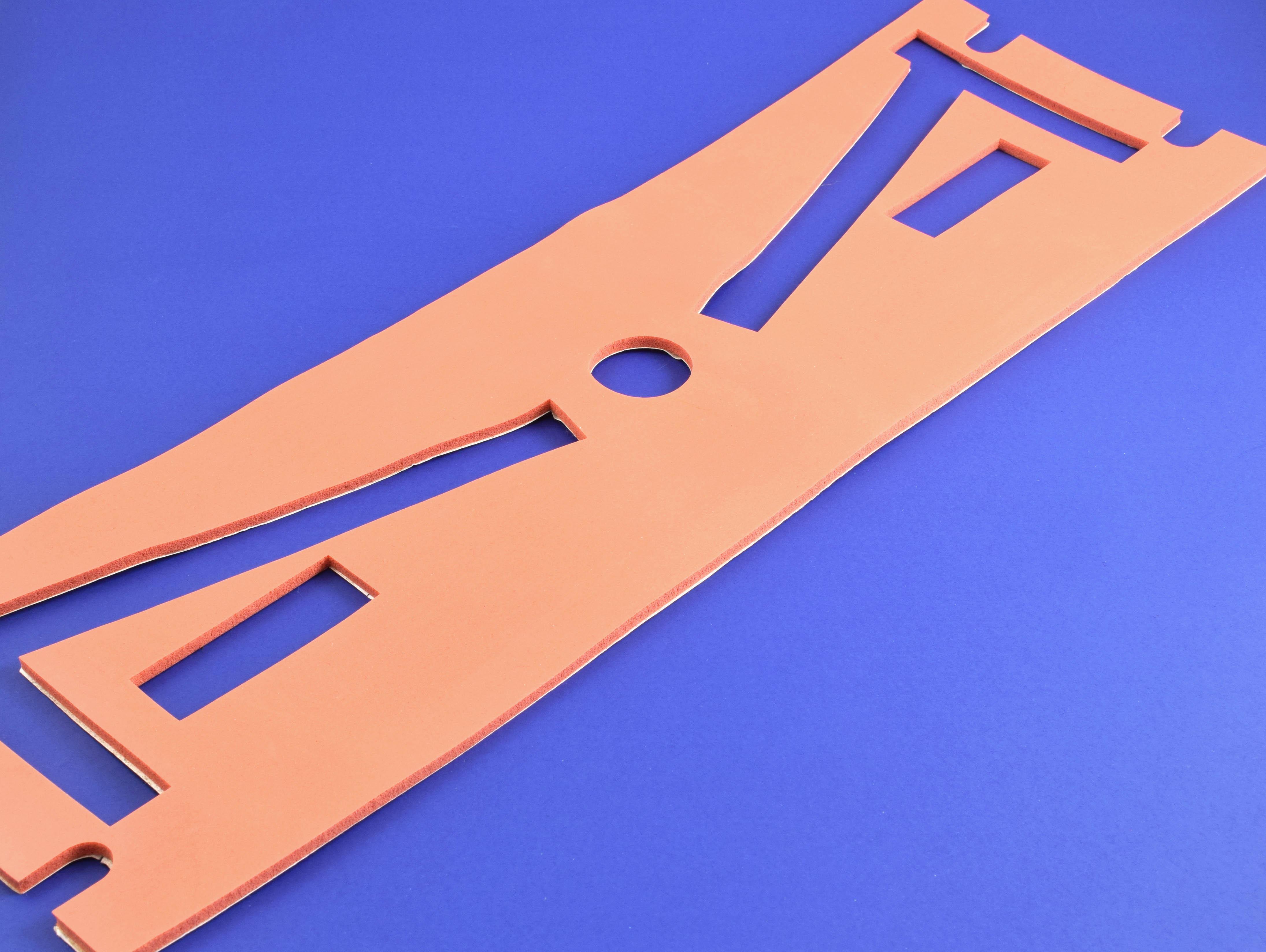

If you’re building a prototype or working on machinery and equipment, you know how important it is to have the right materials. When it comes to amazing substances, it’s tough to beat silicone, especially in the form of custom-cut silicone parts.

Silicone parts are incredibly adaptable to environmental duress, weather, movement, and drastic temperature fluctuations -70° F to 500°F. Depending on their thickness, they can be used for multiple purposes, including:

- Shock absorption

- Vibration and sound dampening

- Sealing to repel liquid

- Mechanical flexibility

- And more

Where Custom-Cut Silicone Parts Can Be Used

Easy answer — pretty much any machines and heavy-duty equipment! Our customers have used custom cut silicone parts in:

- Automobiles (gaskets, seals, heat shields, and more)

- Electrical enclosures (thermal insulation, firestops, and more)

- Industrial machinery (cushioning, acoustical insulation, and more)

- Electronic products and components (thermal gap pads and more)

- Appliances (seals, insulation, and more)

These are only a handful of ways that silicone can be used. If you’re building a product and need more information, please contact us today!

Get a Free Quote On Custom-Fabricated Silicone

American Flexible Products is a nationwide converter of flexible materials—from foam to rubber to silicone. Every product is custom-cut and shaped to your design specs by our materials engineers.

Call (952) 368-4225 or contact us online and our material experts will help you choose the right grade, size, and shape for your prototype.