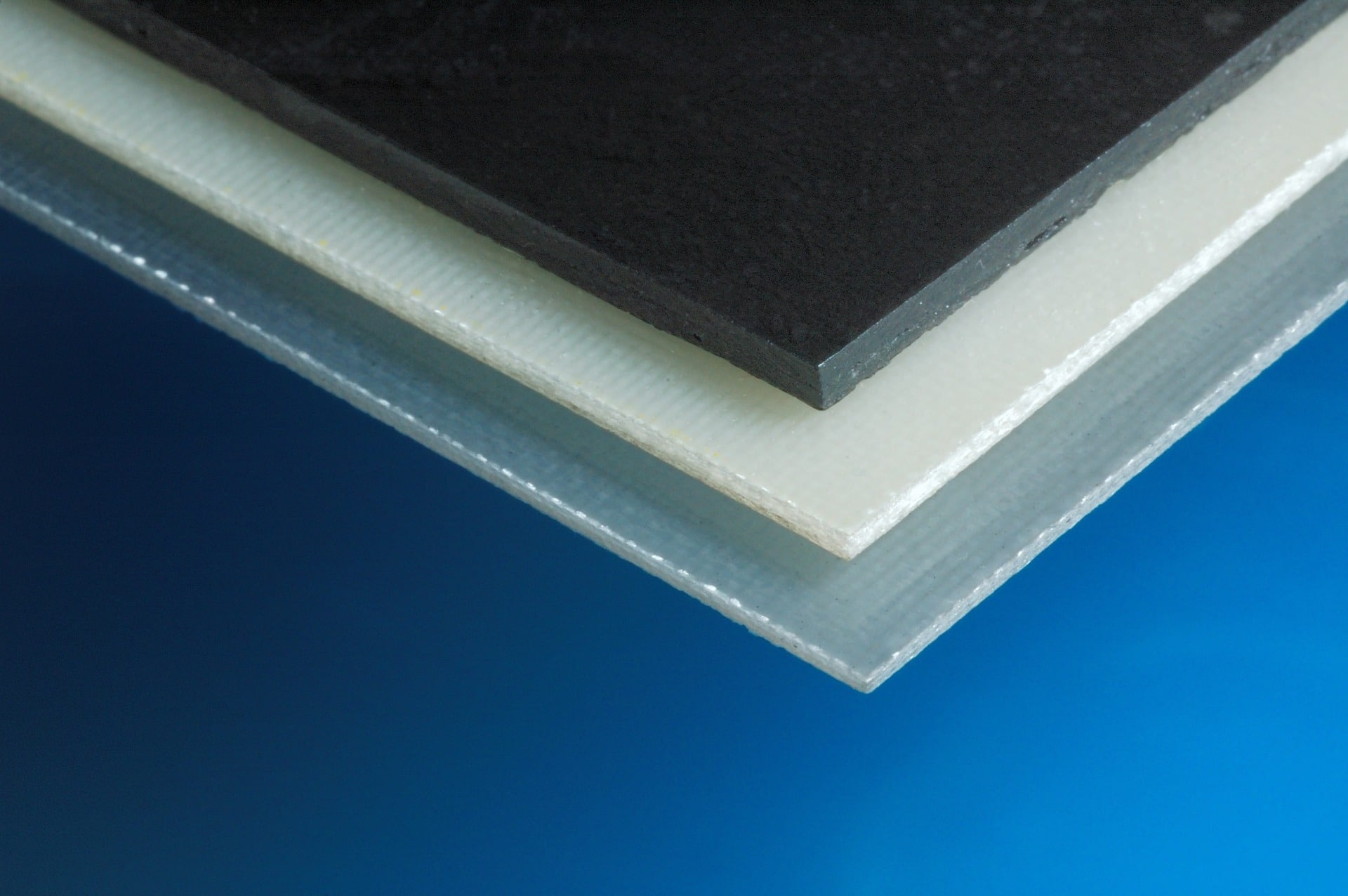

Thin, Even Sheets

When raw materials come thick, it’s our job to slim them down. Our splitting equipment slices off clean, even planes from flexible materials like open cell and closed cell foams, neoprene, silicones and more.

With sharp blades and computer precision, our materials techs cut large sheets that can be rolled up for later use, further shaped here in-house, or used as is. And like the rest of our products, all splitting is custom cut to your design specs—never off-the-shelf.

The Detailed Process

To split material, a steel blade makes a long, even cut along thick sheets of material. These large sheets are cut quickly and accurately, thanks to our computer-controlled equipment.

Split planes are often slit or die cut to create individual parts, like gaskets or seals. Adhesive backing tapes or pressure-sensitive adhesives can be added to the final product.

Once complete, these products are used in machinery, transportation, consumer products—just about anywhere a soft, flexible material can help with safety and function.

Wondering if splitting is right for your parts? Give us a call to talk with one of our engineers. We’ll help you decide which type of shaping is best for your project.

Every call, question and quote request will be answered by an owner.