Tighter Cuts For Thinner Parts

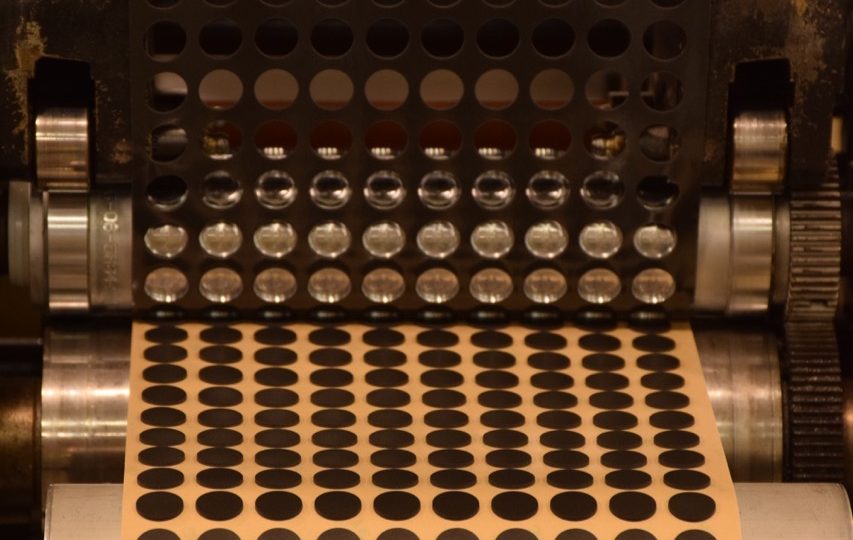

Rotary die cutting puts the spin on shaping parts. For tighter tolerances, faster production, and higher accuracy, rotary die cutters slice materials into the exact size and shape that your custom design specs call for.

Great for thinner gauge materials, rotary die cutting can make either full cuts or kiss cuts, where your product is left attached to a thin, peelable paper lining. Our materials techs can even add a layer of pressure-sensitive adhesive to your product before sending through the rotary die cutter.

When to use Rotary Die Cutting

If your end product will be thin

If you have a relatively large order quantity

If your product requires removable parts on a single backing

If you have tight tolerances in your design

A Deeper Look

When your product is shaped with our rotary die cutters, the raw material is forced through two rotating cylinders at high speeds. This rotation and speed allow for high tolerances and accuracy, and often produces less waste than other types of shaping.

Wondering if rotary die cutting is right for your parts? Give us a call to talk with one of our engineers. We’ll help you decide which type of shaping is best for your project.

Our engineers work with you to shape your parts from top-sourced flexible materials.