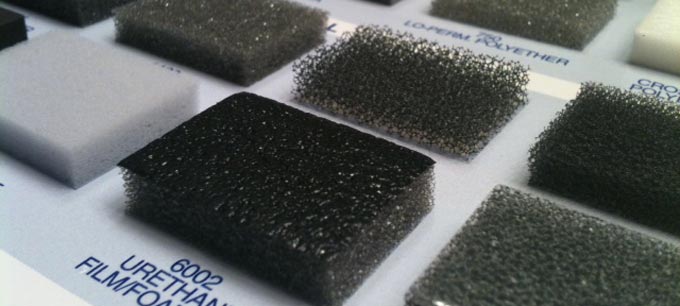

In open cell materials, such as our open cell foam, gas from within the material is released during formation, creating empty spaces. This often allows for a lower density compared to closed cell materials as well as the ability to return to its original state after compression.

Open cell materials are generally more flexible and can conform more easily to sealing applications than closed cell materials. Open cell materials do not resist liquid water or water vapor (such as humidity) and are more often less durable than closed cell materials.

Some open cell materials offer higher performance characters such as low compression set, resistance to chemical environments, and tolerance of extreme temperatures.

Design Criteria

Open cell flexible polyurethane foams meet many design criteria for filtration functions including collecting vaporized oils from industrial equipment, acting as an evaporative surface and removing dust and contaminating particles from air, gases and liquids.

- Filter Foam

- Polyester Urethane

- Polyether Urethane

Some special purpose open cell foams provide higher performance features such as low compression set, resistance to harsh chemical environments and tolerance of extreme temperatures.

Every call, question and quote request will be answered by an owner.

We’re Here to Help

At American Flexible Products, we are dedicated to providing custom solutions tailored to your specific needs. With over 30 years of experience in custom fabricating foam, rubber, plastics, and other flexible materials, our team of experts is ready to assist you in bringing your project to life.

As a 100% employee-owned company, every call, question, and quote request will be answered by an owner, ensuring exceptional customer service and attention to detail.

Whether you’re starting from scratch or know exactly what you need, we’re here to help. Our services include product design assistance, material selection, rapid prototyping, and high-volume production runs.

Contact us today to discuss your project requirements and discover how our expertise can benefit you. Fill out the contact form below, and one of our dedicated specialists will get back to you promptly.

We look forward to collaborating with you and delivering high-quality, cost-effective solutions that meet your unique specifications.

Let's Create Your Custom Solution

"*" indicates required fields