Have you ever wondered what helps to protect aircraft or intricate electrical components from failing in extreme heat conditions?

Heat-resistant tapes are engineered specifically for high-temperature uses, such as aerospace, electronics, and industrial manufacturing. These tapes ensure optimal performance, reliability, and safety in environments where standard materials would fail.

As a 3M™ Preferred Converter, American Flexible Products has supported defense departments, aerospace, and industrial manufacturing in customizing a variety of tapes for their projects. If you’re unsure of what heat-resistant material is best for your application or industry, give us a call.

Today, we’ll explore heat-proof tapes: their materials, benefits, and how they can support your next project. Let’s get started!

Heat-Resistant Tapes for High Temperatures

There are many benefits to using heat-resistant tapes. They can provide circuit insulation, ensure structural integrity, and reduce the risk of heat damage.

You might be thinking, “What qualifies a tape as heat-resistant?” While there are many durable tapes able to withstand temperatures of 250 to 300°F, some heat-resistant tapes can withstand temperatures of 400°F degrees or higher.

Heat-resistant tapes can have different performance classifications based on their material and capabilities:

Fire-proof Tapes are made from materials that can withstand open flames and are commonly used in aerospace to protect components from the intense heat of engines or exhaust systems. These tapes not only resist burning but also help contain fires, minimizing damage and critical failure.

Flame-Retardant Tapes offer critical protection in areas required to meet fire and safety standards, such as cargo bays and aircraft interiors. These tapes are chemically treated to self-extinguish to make them more resistant to extreme temperatures. Flame-retardant space tapes are often used for wrapping, sealing, and electrical insulation.

Heat-Proof Tapes are designed to endure prolonged exposure to high temperatures without degrading. They’re ideal for applications that require continuous heat resistance, such as in engine compartments or power systems in aerospace vehicles.

Heat-Resistant Electrical Tapes provide insulation and protection against electrical currents for components such as printed circuit boards and batteries. These tapes are essential in electronics manufacturing and maintenance, where high temperatures can compromise insulation and pose safety risks.

Next, we’ll explore the types of materials used in heat-resistant products, their tolerance levels, and their uses.

7 Types of Heat-Resistant Tapes and Materials

When it comes to tapes, there are essentially two components—the adhesive and its backing or carrier. Double-coated products may contain two adhesive materials.

There are many factors to consider when choosing the right heat-resistant material. Below are some common materials used to make heat-resistant tapes:

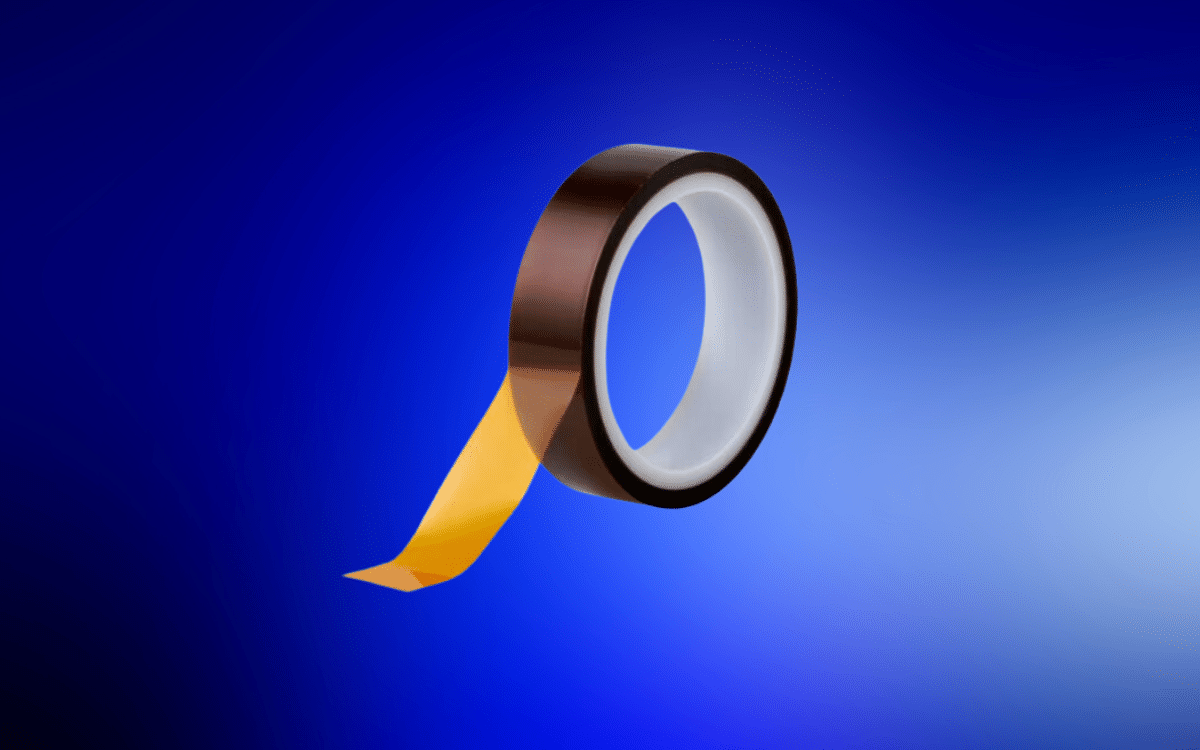

1. Polyimide (Kapton) Tapes

Heat-resistive Polyimide tape, or Kapton tape, can withstand temperatures of up to 500°F (260°C), making it preferred for use in electronics, aerospace, and automotive industries due to its stability under high temperatures.

2. Silicone Adhesives

Silicone adhesives provide good thermal insulation and can withstand temperatures up to 500°F (260°C); however, some may only be suitable for bursts of heat to provide short-term protection, so refer to your product’s technical data sheet (TDS) with any questions.

These adhesives are flexible and resistant to UV radiation, water, and many chemicals. Automotive, aerospace, and electrical applications that require insulation, sealing, or wrapping of high-temperature components, such as furnace insulation, industrial hoses, and engine components, often use silicone adhesives.

3. Glass Cloth

Glass cloth tapes are suitable for high-temperature environments where thermal and electrical insulation are needed, such as protecting aircraft engine compartments or providing coil insulation. Tapes like the 3M™ Glass Cloth Tape 361 can withstand environments ranging from -65°F (-54°C) to 450°F (232°C).

4. High-Temperature Aluminum Foil Tapes

Aluminum foil tape, often referred to as aviation tape or HVAC tape, is designed for a range of specialized applications. Flame-resistant and thermally conductive, this tape is ideal for heat shielding and wrapping over electrical components, withstanding temperatures up to 600°F (316°C).

From HVAC to avionics, aluminum tapes can offer a variety of solutions, including EMI/RFI shielding to protect aircraft from critical failure.

5. 3M™ VHB™ (Very High Bond) Tapes

From bonding lightweight panels and structural components for aerospace uses to protecting electronics during the manufacturing process, 3M VHB Tapes offer exceptional heat resistance and adjust for differences in how materials expand and contract with temperature changes.

Our 3M™ VHB™ GPH High-Temperature Tape offers excellent high-temperature resistance for short-term use of up to 450°F. This allows bonding before powder coating or liquid painting applications for virtually invisible fastening (without the unwanted rivet heads of weld marks).

6. Acrylic Adhesives

High-resistant acrylic adhesives, such as 3M™ F9460PC Transfer Tape, can endure temperatures up to 500°F. These adhesives are ideal for industrial joining and metal fabrication and can adhere to various surfaces, including metals and foams.

7. Polyester (PET) Film Tape

Polyester (PET) film tape is heat-resistant and performs well in moderately high-temperature conditions of up to 400°F. Its polyester backing supports thermal stability, allowing it to endure heat exposure without losing adhesion or strength.

You’ll typically see film tapes used in electronics, electrical insulation, and powder coating. PET film tape also offers reliable protection against abrasion and chemicals.

Things to Consider When Choosing a High-Temperature Tape

Choosing a tape requires careful consideration, as the adhesive and its backing or carrier counterparts may have different tolerance levels to temperature, sometimes up to 100°F apart.

It’s also important to consider the length of time (minutes, days, or weeks) when your product is heat-resistant. Some products may last longer than others, so refer to your product’s technical data sheet if you have any concerns.

Choosing the Best Tape for Your Project

When failure is not an option, American Flexible Products can help you find the best solution for your project. As 3M™ Preferred Converters, Our team of experts works to support aerospace, manufacturing, defense industries, and more in providing customized products and materials cut to your specifications. Contact us today to get started!

Contact Form

"*" indicates required fields