Electromagnetic interference (EMI) is an electronic emission that interferes with the performance of electronic devices. EMI and radio frequency interference (RFI) can disrupt performance in critical systems and equipment used by the military, commercial aircraft, medical industries, and more. In the article below, we cover how EMI shielding works in aerospace applications.

Natural and man-made sources may produce EMI, such as lightning, solar flares, power lines, cellular networks, and high-frequency devices. EMI/RFI shielding applications are vital in ensuring safety and providing optimal system performance.

What is EMI Shielding?

EMI shielding refers to protective manufacturing techniques and materials used in equipment and devices susceptible to external electromagnetic signals. EMI shielding solutions prevent interference with the equipment’s sensitive electrical systems.

Without proper EMI shielding applications, EMI can cause critical damage to avionics equipment, where there’s a high risk of exposure to EMI and RFI. This may result in disruptions or catastrophic failures within navigation and communication systems.

What EMI Shielding Techniques and Materials are Used in Aerospace?

EMI shielding techniques are crucial in the aerospace and defense sectors, where they play a vital role in safeguarding sensitive electronics. These techniques encompass a range of strategies designed to prevent, block, or mitigate the effects of electromagnetic interference (EMI). When implemented correctly, they effectively shield equipment, machinery, and devices from disruptive electromagnetic influences, ensuring optimal performance and reliability.

EMI Shielding Solutions for Aerospace and Defense

American Flexible Products uses electrically conductive and static dissipative magnetic field and radio frequency field-reducing materials powered by 3M™ products to ensure optimal protection against electromagnetic interference.

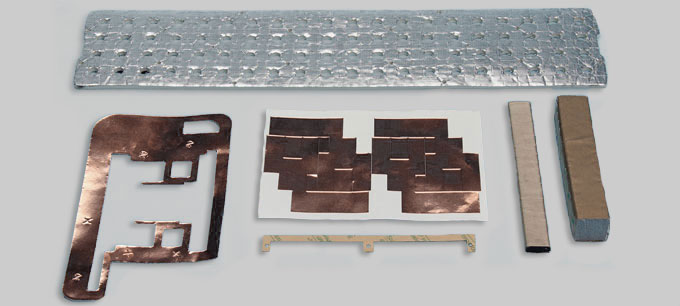

Our products and materials are effective in EMI/RFI shielding, including tapes, adhesives, and gasket tapes.

Electrically Conductive Tapes and Adhesives

3M™ Electrically Conductive EMI shielding tape offers XYZ-axis or Z-axis conductivity and is useful for EMI/RFI shielding and grounding. They come in various types, including single-sided and double-sided tapes, with options for conductive adhesives, carriers, and fillers to enhance EMI performance. Products include:

- 3M™ Electrically Conductive Single-Sided Tape 5113SFT

- 3M™ Electrically Conductive Double-Sided Tape 5113DFT

- 3M™ Electrically Conductive Single-Sided Tape 1050TC

- 3M™ Electrically Conductive Adhesive Transfer Tape 9703

3M™ Electrically Conductive Gasket Tapes

An EMI shielding gasket protects and blocks stray signals or frequencies from meddling with electrical components.

Our 3M™ tapes used are compressible, open-cell urethane foam EMI shielding gaskets with single or double-coated conductive adhesives. XYZ-axis conductivity enables grounding between two surfaces with a wide gap.

3M™ EMI Absorbers

EMI absorbers are flexible composite materials that use specialized magnetic particles and a non-conductive PSA to absorb EMI. Some EMI-absorbing products include:

3M™ Magnetic Shielding Materials (Ferrite Sheets)

Ferrite sheets are thin magnetic materials that interact with and influence electromagnetic fields, shielding sensitive electronic components and circuitry from external low magnetic fields (<1MHz).

3M™ Damping Foil 2552

This aluminum foil tape helps reduce vibration and noise in various applications. Damping foil 2552 controls resonant vibrations through temperatures ranging from -25°F/-32°C to 175°F/80°C with peak damping from 32°F/0°C to 140°F/60°C.

3M™ Damping Aluminum Foam Sheet 4014

Damping aluminum foam sheets weaken and reduce resonant sound and vibration in thin sheet metal, plastic panels, and support structures.

EMI/RFI Applications in Avionics and Aerospace

Below are three additional protective applications used in avionics and aerospace to ensure optimal GPS and radar performance.

Aircraft and Drone Avionics

- 3M™ Thermally Conductive Tapes can protect flight instruments from slowing down and 3M™ Thermally Conductive Adhesive Transfer Tape 8810 helps maintain flight safety and efficiency by keeping GPS systems cool.

- 3M™ EMI Absorber AB7050HF(S) or 3M™ Flux Field Directional Materials protect electronics by absorbing EMI/RFI over a wide range of frequencies.

- 3M™ Electrically Conductive Adhesive Transfer Tapes can shield engine data displays from disruptive EMI and RFI.

AEW&C and Scanning Array Radar

3M™ EMI Absorber AB7050HF (for higher frequencies) and 3M™ EMI Absorber AB5050HF (for lower frequencies) absorb unwanted signals and help ensure accurate radar readings.

Seat and Display

- 3M™ Electrically Conductive Adhesive Transfer Tapes protect against electrostatic discharge (ESD) by grounding an electrical path, while 3M™ Thermally Conductive Adhesive Transfer Tape 8810 protects LED displays from heat.

- 3M Anisotropic Conductive Film 7303 helps create a smaller and lighter electrical path compared to other connectors.

Questions About our Products?

Contact us for more information on materials and solutions that fit your unique needs.