Any product that generates heat can become damaged if its components aren’t protected from overheating. Thermal interface materials (TIMs) are designed to help components transfer heat more effectively. They do this by filling air gaps between surfaces, allowing heat to dissipate, which keeps parts at an ideal temperature.

Several types of TIMs are available, such as thermal paste, grease, and pads. In this blog post, we’ll explore thermally conductive interface pads, including how they work and how to install them for optimal performance. We’ll also discuss how to choose the best 3M™ thermal pads for any application.

Understanding 3M™ Thermally Conductive Interface Pads

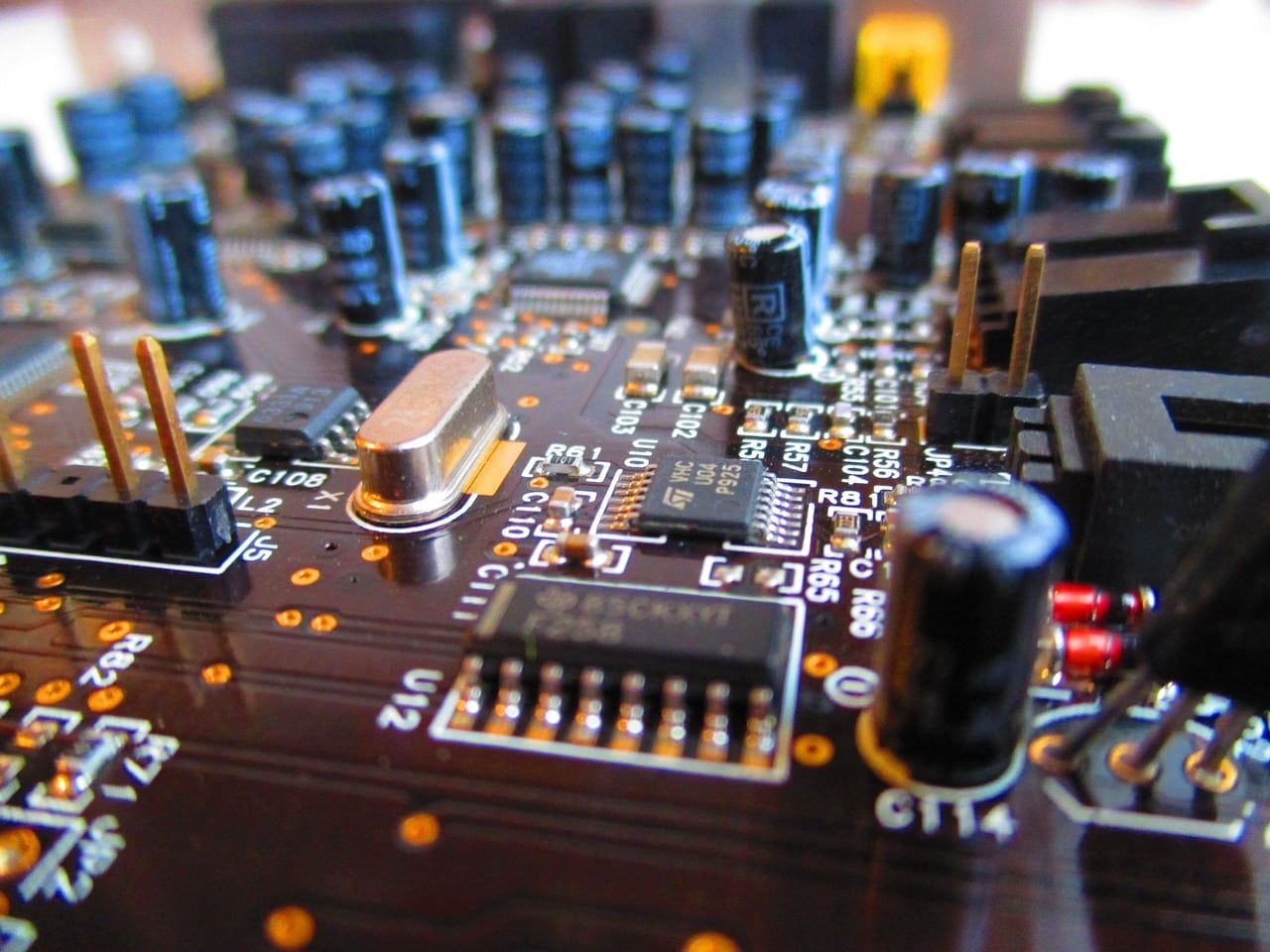

All electronic devices produce some level of heat. That heat needs to be transferred or dissipated properly so the components don’t sustain – or cause – damage. When components don’t touch one another, the air between them increases thermal resistance, causing parts to get too hot.

This is where thermal pads come in. Even when surfaces appear smooth or connected, even the smallest amount of air between two components can prevent optimal heat transfer. Thermal pads are designed to fill the gap, allowing parts to make full contact and dissipate heat significantly better.

3M™ thermal pads and other TIMs are commonly used in:

- Gaming consoles, cell phones, PCs, and other electronics with a CPU.

- Engine control modules (ECMs), power inverters, and other electric components in vehicles.

- Industrial applications such as power supplies, motor drives, and automation systems.

- LED lighting systems, including tube bulbs, strip lights, and other bulb types.

Selecting the Right 3M Thermal Interface Pad

Thermal pads are useful for a wide range of applications. However, there are several 3M™ thermal interface materials to choose from. The best option will vary by application.

When choosing a material, consider these factors:

- Thermal Conductivity: Some devices produce more heat than others. Make sure you choose a pad with enough thermal performance to keep your device cool.

- Thickness and Compressibility: To transfer heat properly, a thermal pad has to be the right thickness. A pad that’s too thick will actually hinder conductivity, while having one too thin will result in overheating.

- Dielectric Properties: Choose a material that will provide electrical insulation if it comes in contact with components that produce electricity.

- Adhesion and Tackiness: Self-adhesive pads are available with varying levels of stickiness, while non-adhesive pads will not stick on their own. The type you need may depend on your application.

- Operating Temperature Range: Make sure to choose pads that are rated for the temperature range that your device will operate in. Consider both the heat produced by the device itself and the environmental conditions it will be in.

Numerous models of 3M thermal pads are available with different specs, so you can find exactly what you need for any device. With the wide variety of options available, we know choosing can be difficult. Give us a call, and we’ll be happy to help you find the best option for your application.

Preparing for Installation

Before installing 3M™ thermal pads, it’s important to prepare the surface so the pads will work properly.

First, you’ll want to gather any tools you might need to dissemble the component. You don’t need any special tools to install the pads. However, tweezers can be useful for peeling the plastic film from the new thermal pad.

One of the benefits of using thermally conductive interface pads is you don’t typically need to wear gloves while handling the material, unlike thermal paste or grease. However, you do want to be careful with how you store the pads. It’s a good idea to keep the original packaging and store any unused material in a cool, dark place away from chemicals and sharp objects.

After getting your tools together, you can prepare the surface for installation. If you’re replacing an existing thermal pad, start by peeling it from the device and removing any residue or debris. Isopropyl alcohol works well on many surfaces. However, check with the manufacturer for approved cleaning solutions to prevent damage.

Step-by-Step 3M Thermal Pad Application Guide

3M thermal interface installation is easy. Simply follow these steps:

- Measure the area so you can obtain the correct size of thermal pad. You want the pad to cover the heat-producing element where it makes contact with other components.

- If using an adhesive pad, remove the film from one side and align the sticky side with the heat-generating component.

- Apply gentle, even pressure to ensure the pad is adhered properly.

- Peel the protective film from the top side and place the corresponding component on the pad in its correct position.

- After installation, test the device to ensure it performs as expected.

When installing pads, there are a few things you’ll want to avoid:

- Don’t stack pads together to create more thickness. When thermal interfacing is too thick, it can actually hinder performance and cause overheating.

- If you’re removing a component that has an adhesive pad, replace the material before reinstalling the part – even if the original pad appears undamaged. Reusing the material will affect performance.

- Unless the instructions for your thermal pads tell you to do so, don’t combine pads with other TIMs. For example, you don’t usually want to apply both thermal paste and pads to the same area.

Conclusion

Thermally conductive interface pads offer an excellent solution for heat-sensitive components. By choosing the right pads and installing them properly, you can keep devices operating at an ideal temperature, boosting their performance and extending their lifespan.

Choosing the best 3M™ thermal pads can be challenging with the number of different options available. As an authorized 3M™ Preferred Converter, you can trust the experts at American Flexible Products to help you find the best material for any application.

Contact us today to learn how we can help. As a 100% employee-owned company, every inquiry is answered by an owner.