Polyimide material is a high-performance polymer that has become indispensable across various industries due to its exceptional thermal stability, mechanical strength, and chemical resistance. Whether in the aerospace sector or in electronics, polyimide plays a crucial role in ensuring components perform reliably under extreme conditions.

Breaking Thermal Barriers

Polyimide is a type of polymer that is known for its ability to withstand high temperatures without losing its shape or performance. It is made from aromatic compounds and is a thermosetting polymer, meaning it hardens when heat is applied.

The key benefits of polyimide material include:

- High-Temperature Resistance: Polyimide can withstand extreme temperatures of up to 500°F (260°C) and beyond.

- Lightweight and Flexible: It’s ideal for aerospace and electronic components where weight and flexibility are crucial.

- Exceptional Dielectric Properties: These properties make polyimide the go-to material for insulating circuits and wiring in high-performance environments.

Polyimide is used in a wide range of industries due to its ability to handle extreme conditions.

Industrial Thermal Solutions

In the electronics and semiconductor industries, polyimide is used in the form of Kapton® polyimide film, one of the most popular insulation materials. This film is commonly used in flexible circuits, heat-resistant cables, and electronic enclosures.

Polyimide’s non-conductive nature and excellent heat resistance prevent overheating in sensitive microelectronics, making it a vital material for applications like PCBs, transformers, and high-performance semiconductor packaging.

High-Temperature Polyimide Applications

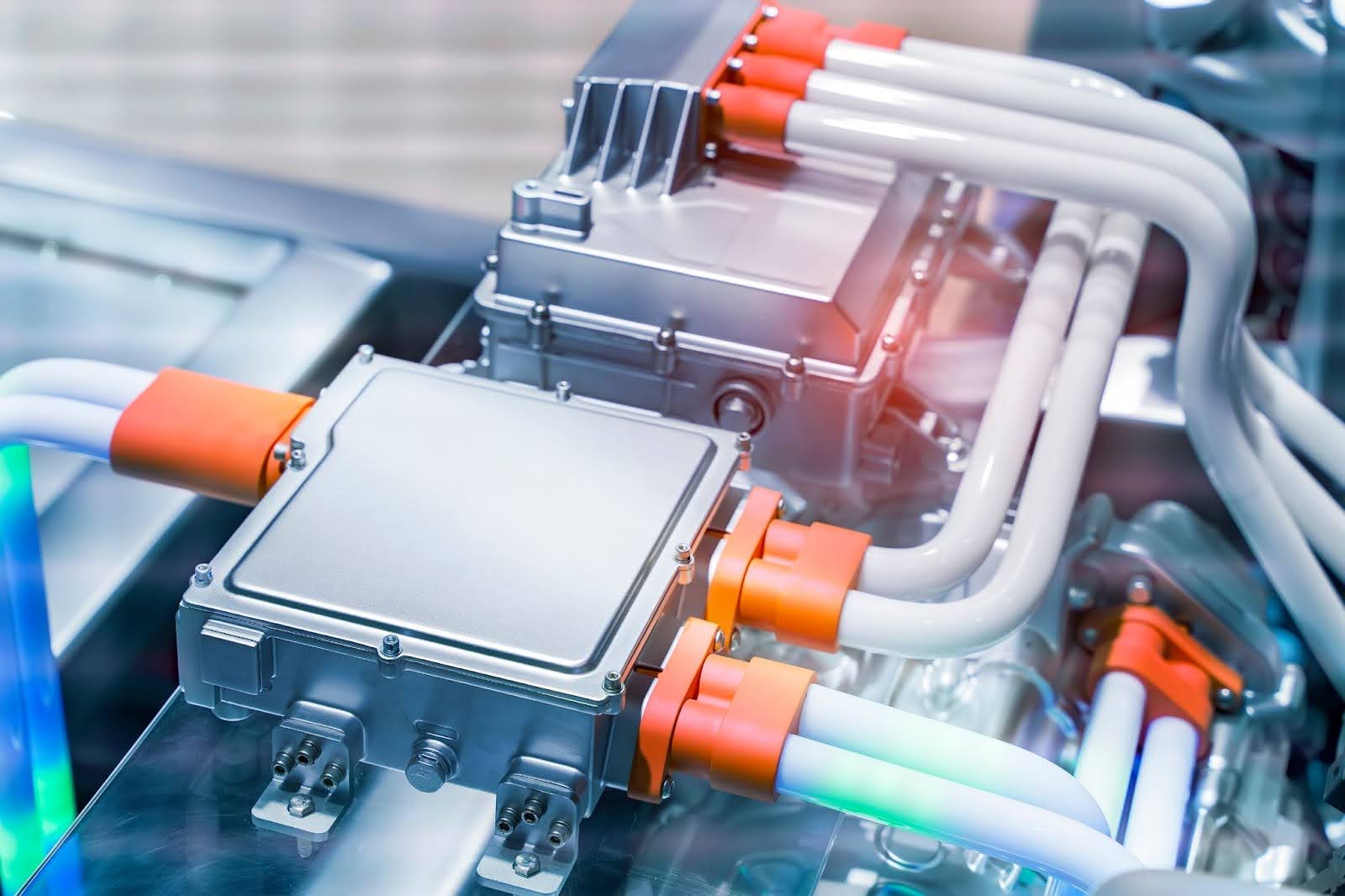

Polyimide material also excels in automotive and industrial applications, where its heat resistance is used in gaskets, seals, and thermal barriers. In high-performance vehicles, polyimide ensures that thermal solutions function at their best, preventing overheating in combustion engines and EV batteries.

Its superior thermal properties reduce thermal expansion issues, ensuring long-term material stability, making it an ideal choice for demanding industrial environments.

Comparing Polyimide to Other High-Temperature Insulation Materials

Here’s a high-level view on other materials comparable to polyimide:

| Material | Temperature Limit | Key Benefits | Best Uses |

| Polyimide | 500°F (260°C) | Lightweight, flexible, high dielectric strength | Aerospace, electronics, industrial thermal barriers |

| Silicone Rubber | 450°F (232°C) | Weather-resistant, flexible | Gaskets, seals, automotive |

| PTFE (Teflon) | 500°F (260°C) | Chemical resistant, non-stick surface | Electronics, industrial sealing |

| Ceramic Fiber | 2,300°F (1,260°C) | Extreme heat insulation | Furnace insulation, industrial applications |

Industrial Thermal Solutions- American Flexible Products Has You Covered

At American Flexible Products, we specialize in providing high-quality, custom-made polyimide solutions tailored to your specific needs.

We offer:

- Custom-Cut Polyimide Solutions: We offer die-cut, laminated, and precision-fabricated polyimide components to ensure that your insulation applications meet the highest standards.

- Kapton® and 3M™ Polyimide Film and High-Performance Thermal Materials: We provide quality Polyimide Film, such as Kapton®. We also work with thermal materials from industry-leading brands 3M™ and Rogers Corporation.

- Industry Expertise in High-Temperature Solutions: With years of experience, we support aerospace, electronics, and industrial manufacturers in finding the most effective thermal barrier solutions for their applications.

If you’re looking for high-quality, custom polyimide solutions, American Flexible Products is here to provide you with the expertise and materials you need to meet your performance goals. Contact us today and see how polyimide material can elevate your next project.