Harness the Power of Water

Water has never been so powerful yet so precise. With waterjet cutting, your parts can be shaped, sheared and sliced using nothing but cold water and a bit of pressure.

Our waterjet equipment shoots out a powerful, steady stream of water that cuts through materials both soft and firm. And with a max pressure as high as 90,000 psi, your end product comes out clean, accurate and ready for use.

Why Waterjet Cutting?

Unlike other methods of precise shaping (like laser cutting), waterjet cutting doesn’t use heat. Some materials will warp or burn when heat is applied. Our engineers avoid this by using non-heated water streams and temperature-controlled materials.

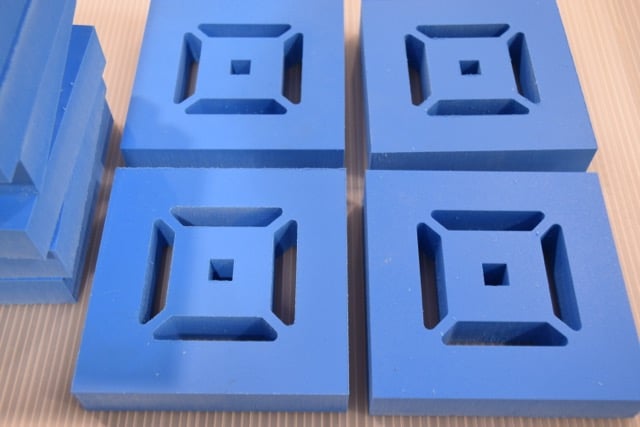

Waterjet cutting can also cut intricate, complex designs into your parts. With our computer-controlled equipment, the accuracy of our waterjets is as low as .025 millimeters, making tight tolerances and level, accurate edges—even with thicker material.

Abrasive Cuts

Depending on the material being cut, we’ll mix an abrasive compound with the water stream (commonly called “abrasive jet cutting”). This highly pressurized stream of water and abrasive can cut nearly any material, including multiple layers with different densities:

Wondering if waterjet cutting is right for your parts? Give us a call to talk with one of our engineers. We’ll help you decide which type of shaping is best for your project.

Every call, question and quote request will be answered by an owner.