A Coating of Durability

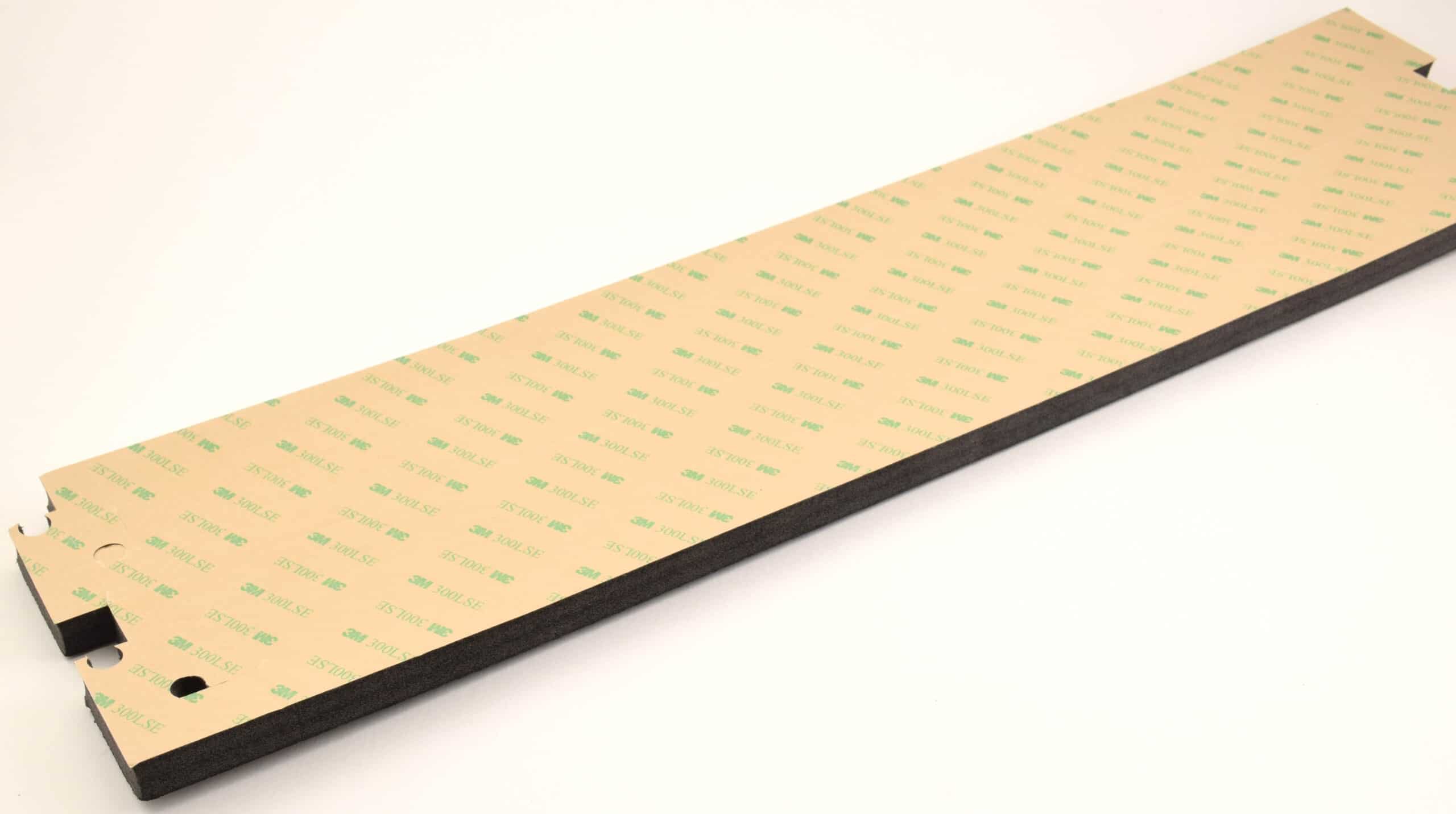

Add protection. Increase strength. Up durability and resilience. Lamination is more than just an added layer. Your parts can last longer and perform better with just a thin coating of laminate film.

We’re all about precision. We use equipment that gives us full control over temperature and pressure. This ensures bond strength without distorting your product.

Since there are benefits to laminating raw material before shaping your product as well as after, our materials techs can recommend when to add a laminate in order to get the best results.

Materials

We laminate substrates from roll stock, sheet stock, and cut and shaped parts, like gaskets, seals, bumpers, spacers and more, made from materials like:

- Films

- Fabrics and textiles

- Closed cell foams

- Foils

- Open cell foams

- Pressure-sensitive adhesives

Have a part that’s a little more complex? We laminate multiple materials together, the same material to itself, add plastic film onto the material—whatever your part needs. If you need help with development, we’ll guide you through materials and shaping methods to make sure your part functions correctly.

Benefits

- Thicker

- Stronger

- Denser

- Heat-resistance

- Protection against liquids and gases

- Liquids and gases containment

Wondering if lamination is right for your parts? Give us a call to talk with one of our engineers. We’ll help you decide which type of shaping is best for your project.

Our engineers work with you to shape your parts from top-sourced flexible materials.